It's been about 5 years since we moved into our new headquarters in Nuremberg, and, starting in 2017, we've not only implemented facility-wide monitoring of room air quality (involving various sorts of sensors), but also a respectable PV system.

Check out how we came to be where we are now – a completely monitored office building – and how exactly we generate the data that shows a lot about how we work and what our company purposes are.

This article is structured into the following sections:

🚀 Our start with IoT

Our start with the IoT world was inspired by the maker culture. Back in late 2017, we installed some devices to monitor the temperature in one location on each floor of our PHQ, as well as in our bistro. We wanted to realize all this not with high-priced consumer products, but ideally with a self-developed IoT solution, following the "maker philosophy". The entire solution should cost only a few bucks and require as little maintenance as possible.

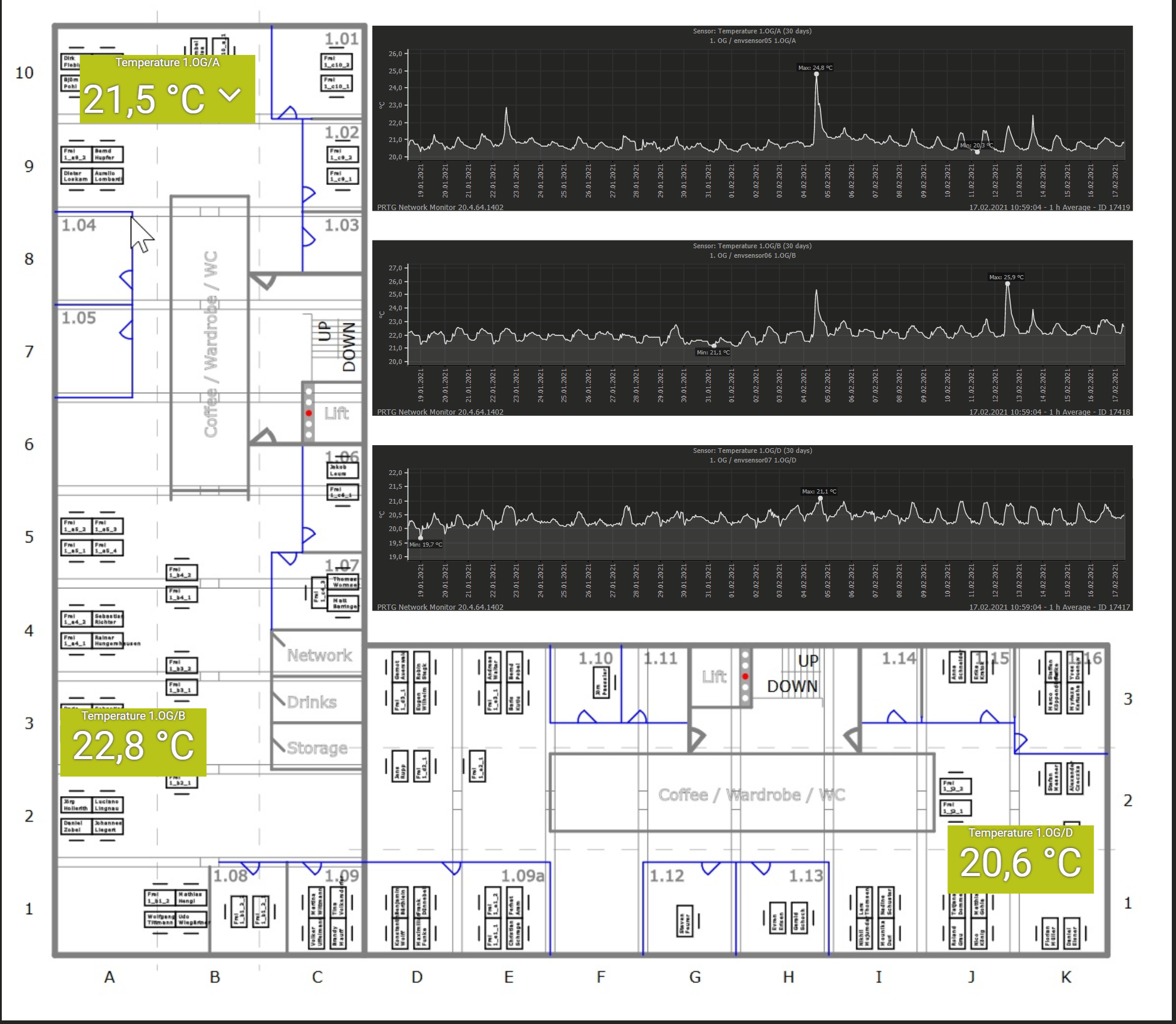

While our journey started with reusing a few existing devices, in early 2020 we had our entire office from top to bottom fully equipped and monitored – right in time for the coronavirus lockdown. 😉

Reuse of things - on a budget

Back in 2017, we looked at what IoT devices various colleagues already used in-house for testing and development purposes ("reuse of things"). While also discussing other options, we came up with the idea that we could implement the existing Arduino devices we used at the Nürnberg Digital Festival workshop the summer before. We introduced an IT intern to the world of IoT, explained how Arduino devices and the Sigfox cloud work, and showed him how to transfer the measurement data to PRTG Network Monitor.

Making it pretty

The next challenge was to supply the devices with electricity and to encase them in an aesthetic housing. PoE (Power over Ethernet) to USB adapters allowed us to use our existing in-line cabling. This gave us full flexibility in the placement of the devices. In the end we had 13 units sending data and ready to be installed all over our office.

The next chapter

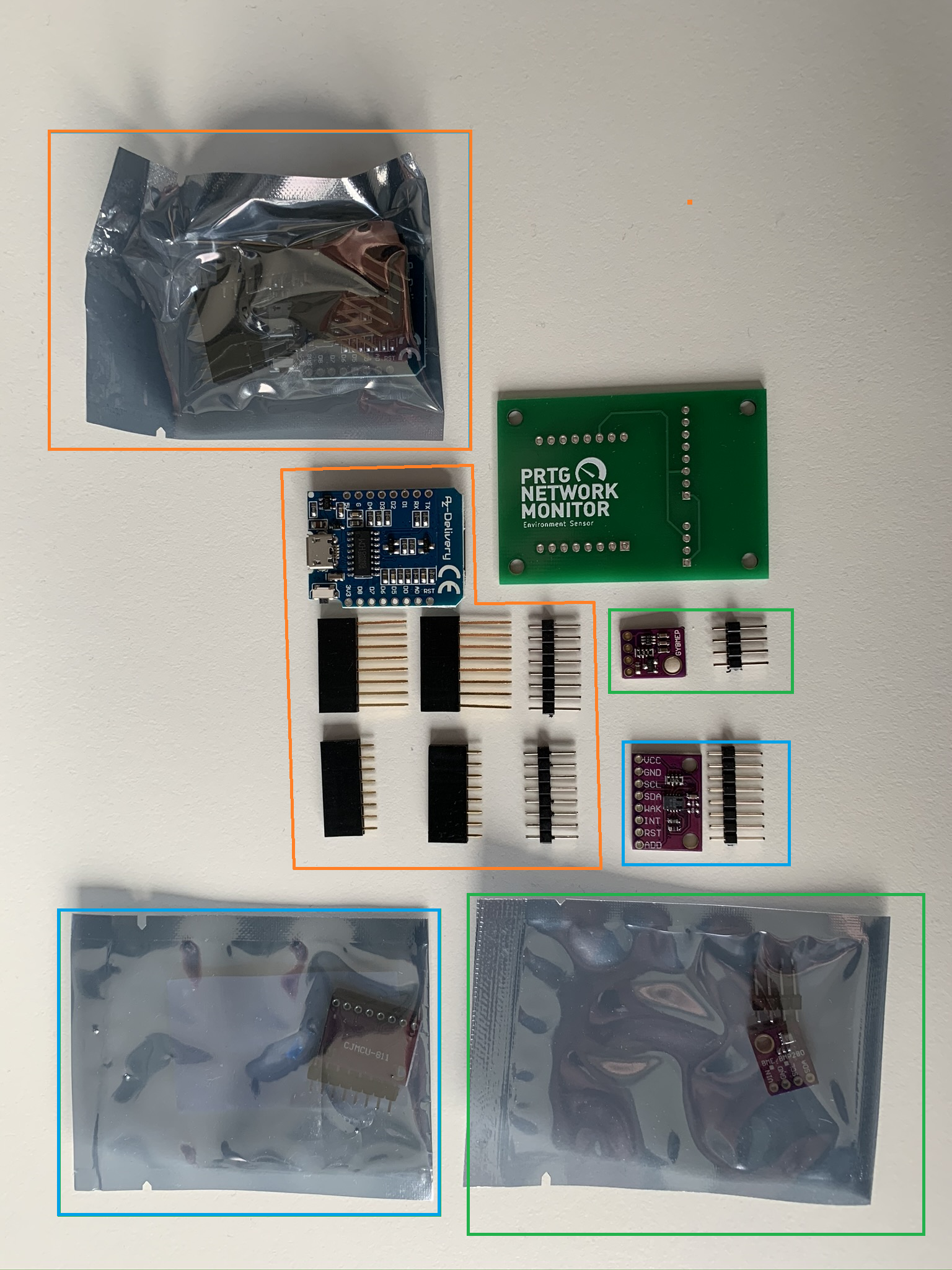

After working with the solution above in parts of our HQ for quite some time, we decided to extend the existing monitoring to cover the entire building, including the basement areas, and again worked on our own set of devices for this purpose. We used the BME280 and the CCS811 sensors in combination with the ESP8266 microcontroller. With this WiFi solution, we created a fast, comprehensive monitoring solution that delivers data in 5-minute intervals via HTTP packets to the HTTP push sensor in PRTG.

As it turned out, launching in early 2020 was not such a great idea after all, because it was that month that most of our co-workers were sent home to work remotely for the good part of the year. The described sensors mainly measure VOC (Volatile organic compound) and as such would be very well suited for offices during COVID19, but there are still too few employees working permanently in our HQ for us to present meaningful data. VOC, by the way, is very suitable as a reference parameter of room air quality (and probably also relatively approximate to the measurement of aerosols).

2021 and beyond

As you can see, monitoring our PHQ with sensors designed and built specifically for our needs is a process that is certainly not yet at an end. We continue to gain a lot of useful experience and practical input from projects we are carrying out with customers or for facilities in the context of the ongoing pandemic, such as the implementation of indoor monitoring of air quality in schools.

🖨️ From CO₂ ppm to our printers

Yes, we're a partly remote working company now, not just during pandemic times, but for good. Still many of our coworkers have their regular desks in our PHQ and beside some exceptions, we're open-space. When "in normal times" twenty people suddenly sit together in a large room, some problems will arise that can be counteracted with appropriate sensors.

Luckily, there are numerous good room air quality sensors on the market that detect CO₂ ppm levels, humidity, pressure, temperature and, as mentioned above, a large number of volatile organic compounds (VOCs). So it's not even necessary to individually build devices; they can be purchased at fairly low prices (leaving out the fact that, due to the current increased demand, you shouldn't try to purchase a good CO₂ sensor right now).

-1.png?width=3020&name=MicrosoftTeams-image%20(1)-1.png)

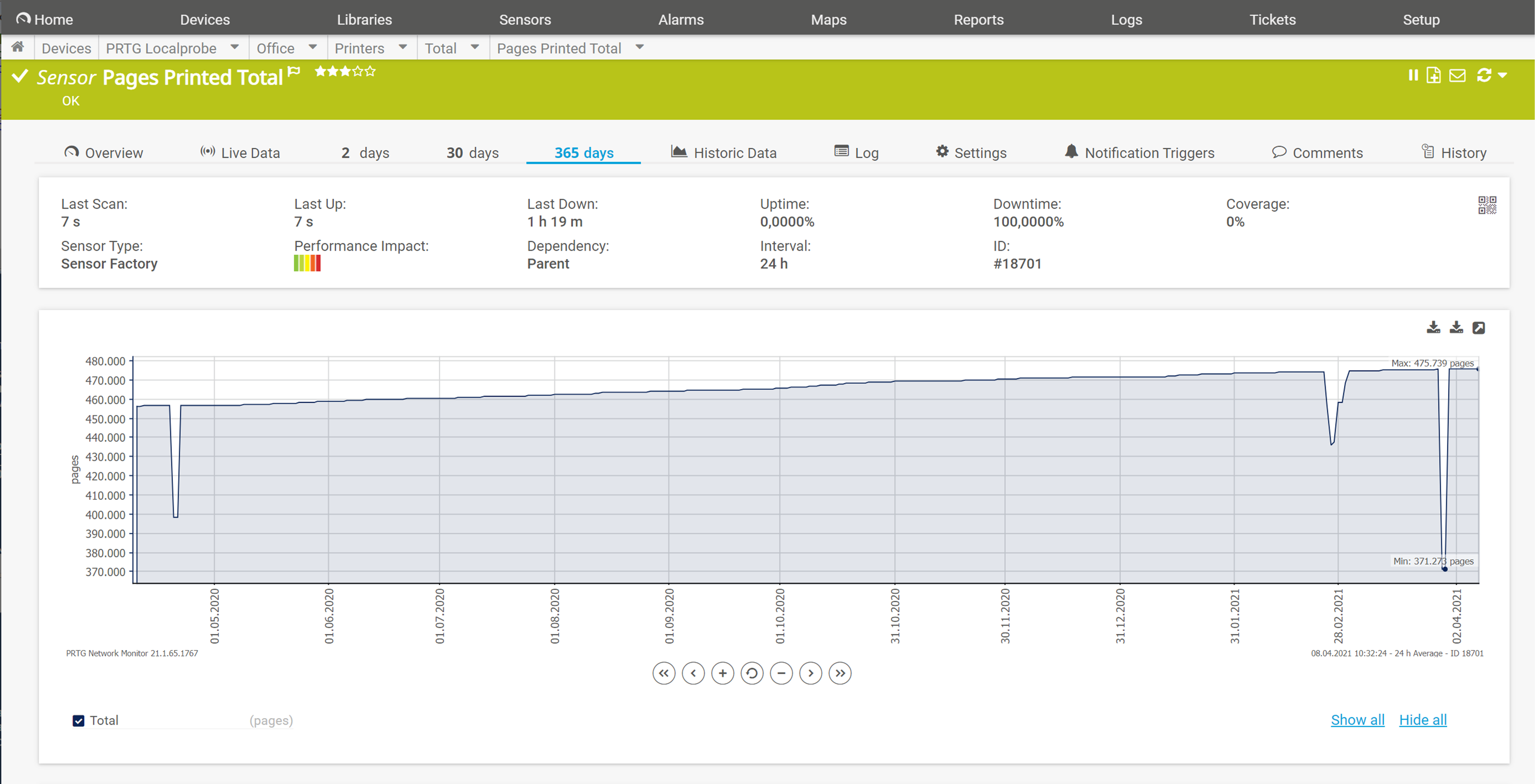

We of course also monitor other details of our daily office routine. For example: the function and values of our various printers. We attach great importance to paperless work (without hampering our colleagues who simply find it easier to work with paper). The downward spikes show printers that were briefly turned off.

🌤️ The victory of sustainable thinking

The work of the future must be based on sustainable strategies. This can be reflected in specific processes, the actual design of the workplaces, or in the way we handle energy resources. More and more employees are looking for employers that try to minimize their environmental footprint. We at Paessler try to reduce our energy consumption and at the same time produce part of our energy ourselves. To do this we installed our own photovoltaic system some time ago, and enough time has passed to show us great data.

Our CO₂ reduction

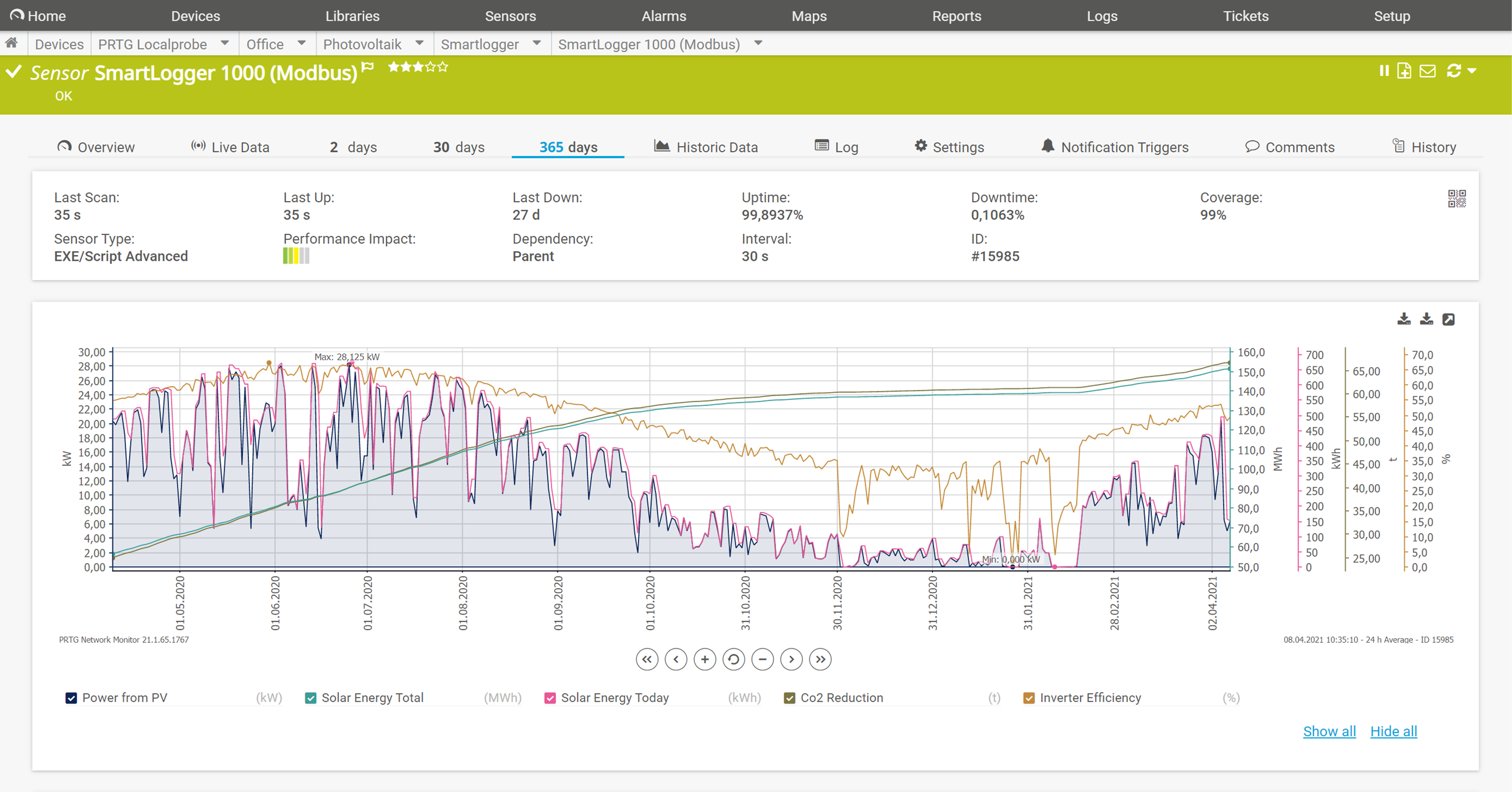

Over a time period of 12 months, we see here the power in kW, the total amount of produced solar energy, the selective daily output, the overall CO₂ reduction, and the inverter efficiency in %:

To generate consistent power throughout the day, we have installed our PV system in an east/west direction. Here's another screenshot we took before noon on a day at the end of October last year. The output was just about 19.8 kW, which would be expected for this time of day in October:

.png?width=709&name=Screenshot_2021-02-12%20You%20wouldnt%20believe%20what%20weve%20learned%20in%20one%20year%20after%20installing%20a%20PV%20system%20on%20our%20roof(1).png)

Our electricity bill

We have also taken a good hard look at our electricity bill and discovered that, depending on the billing period, we generate between a third and half of the electricity consumed in our Nuremberg HQ. We based our calculations mainly on the electricity consumption of 2019, otherwise the particular situation with remote work in 2020 and 2021 would have resulted in different values. However, since we did not generate solar energy for the whole of 2019, the figures will be much clearer when we have had the opportunity to live out our three new work models for a longer period.

Green mobility

As an additional incentive to change our own commuting behavior, we offer each employee the opportunity to charge their electric car at our two charging stations. For free. Since this offer has been well received, we will probably soon upgrade to three charging stations. Here is an interesting monthly overview of loads of 2020 (the sudden drop in spring was of course due to the nationwide lockdown in Germany and the subsequent remote work time):

.png?width=709&name=Screenshot_2021-02-12%20You%20wouldnt%20believe%20what%20weve%20learned%20in%20one%20year%20after%20installing%20a%20PV%20system%20on%20our%20roof(2).png)

And the specific values of our two charging stations can best be seen here:

.png?width=709&name=Screenshot_2021-02-12%20You%20wouldnt%20believe%20what%20weve%20learned%20in%20one%20year%20after%20installing%20a%20PV%20system%20on%20our%20roof(3).png)

Continuing our strides to be an environmentally-conscious company, we are already climate neutral, and it is part of our purpose to further consolidate this and become climate negative in the long run.

🤷 Are there any limits? Not really…

The question of what can be monitored, displayed and improved in a modern office is not useful. The question should rather be: What's still impossible to monitor? And the simple answer: Nothing; at least nothing that we can think of when writing this article. Sensors can be attached to windows and doors. Heating and electricity costs can be reduced. Room temperature, humidity for indoor plants, the next departure time of nearby public transport...this list could be made much longer.

With the right tools, everything that can be monitored will sooner or later be monitored.

Published by

Published by