Whether you call it Industry 4.0, IIoT or Smart Manufacturing, the objective behind these trendy buzzwords is the same - to “connect all the things”. Whether you're responsible for a segment of critical national infrastructure, production lines in a thingamabob factory or a small family run farm; instrumenting and collecting data from your production environment can transform your business in terms of efficiency, cost savings and profitability. As Sir Francis Bacon (among others) observed “scientia potential est” or “knowledge is power”.

The data collected from properly instrumented machinery can be analyzed to reveal hidden information, patterns, and trends. Allowing operators to optimize the running of their environments, reducing costs and minimizing downtime.

If you’re fortunate enough to be working in a modern facility, built within the last few years, there’s a good chance your production equipment already has telemetry collection and monitoring built in. Whether it’s a complex, country spanning SCADA system featuring multiple layers of RTUs, PLCs and HMIs; or a simple, network connected, temperature sensor or a loadcell in a weighbridge; the data generated by these connected devices can provide invaluable insights into the health and performance of the equipment they monitor.

But what about older sites - of which there are literally millions – still running equipment that is many years or even decades old? How do these so called “brownfield” facilities tap into the wealth of data hidden inside their plant and machinery?

The answer is “industrial retrofitting” or “secondary sensing” as it's sometimes called. This is the practice of equipping legacy equipment with additional sensors to gather data for IIoT applications like condition monitoring or predictive maintenance. Such sensors are exclusively used for the IIoT use case and as such, are completely separated from the actual production environment. This means they are unable to interfere with machines or PLCs being monitored and therefore pose less of a security risk than natively integrated telemetry systems.

In addition to the reduced security risk, retrofitting brings other advantages:

- Faster Realisation – No fundamental changes needed to the production environment as no PLC programming is required.

- Reduced Costs – Little to no machinery downtime, and reduced workload for automation engineers.

- Richer Data Quality – Generic sensors can be custom configured, unlike pre-programmed OEM solutions. Sensor networks can easily scale with the IIoT use-case.

The Outlook Is Cloudy

Adding sensors to machines is only part of the story. You also need to be able to analyse the data they collect and transform it into actionable information. This, of course, needs the right software solution. Fortunately, our Alliance Partner Skysens has you covered for both the hardware and software elements of your industrial retrofitting journey.

The Skysens platform is completely hardware agnostic and can work with endpoint and gateway devices from all the leading IoT/IIoT brands. In addition, they also produce their own range of sensor hardware for industrial, Smart Building/City/Agriculture, and even disaster relief applications.

Available in different IP rated enclosures, supporting different protocols (Modbus RTU, IEC, RS232 / 484, etc) and with fixed power or battery options, the Skysens sensors offer maximum flexibility.

The range of sensors available include:

- Agricultural – soil moisture & temperature

- Environmental – temperature, humidity, IAQ, pressure

- Energy Meter – power & consumption

- Acceleration – 3 axis measurement

- Locational Tracking – GNS & GNSS tracking

Many of the sensors support LoRaWAN connectivity, a globally available Low Power Wide Area Network (LPWAN) technology, providing long range communications, with low power requirements.

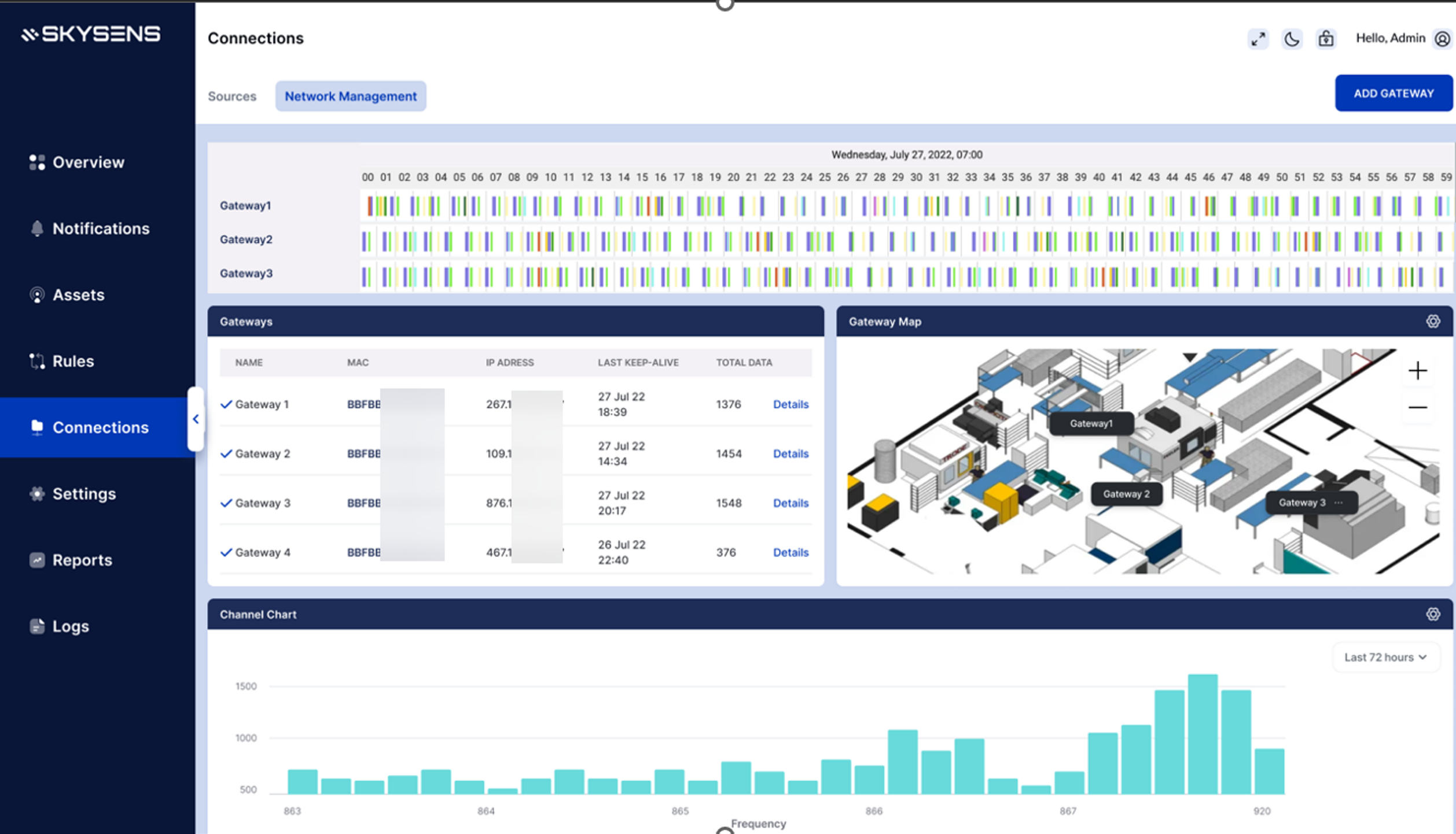

The Skysens platform also provides a private LoRaWAN Network Server as an integral part of the system. This makes it easy for users to manage wireless network, gateways, and devices from a single unified console.

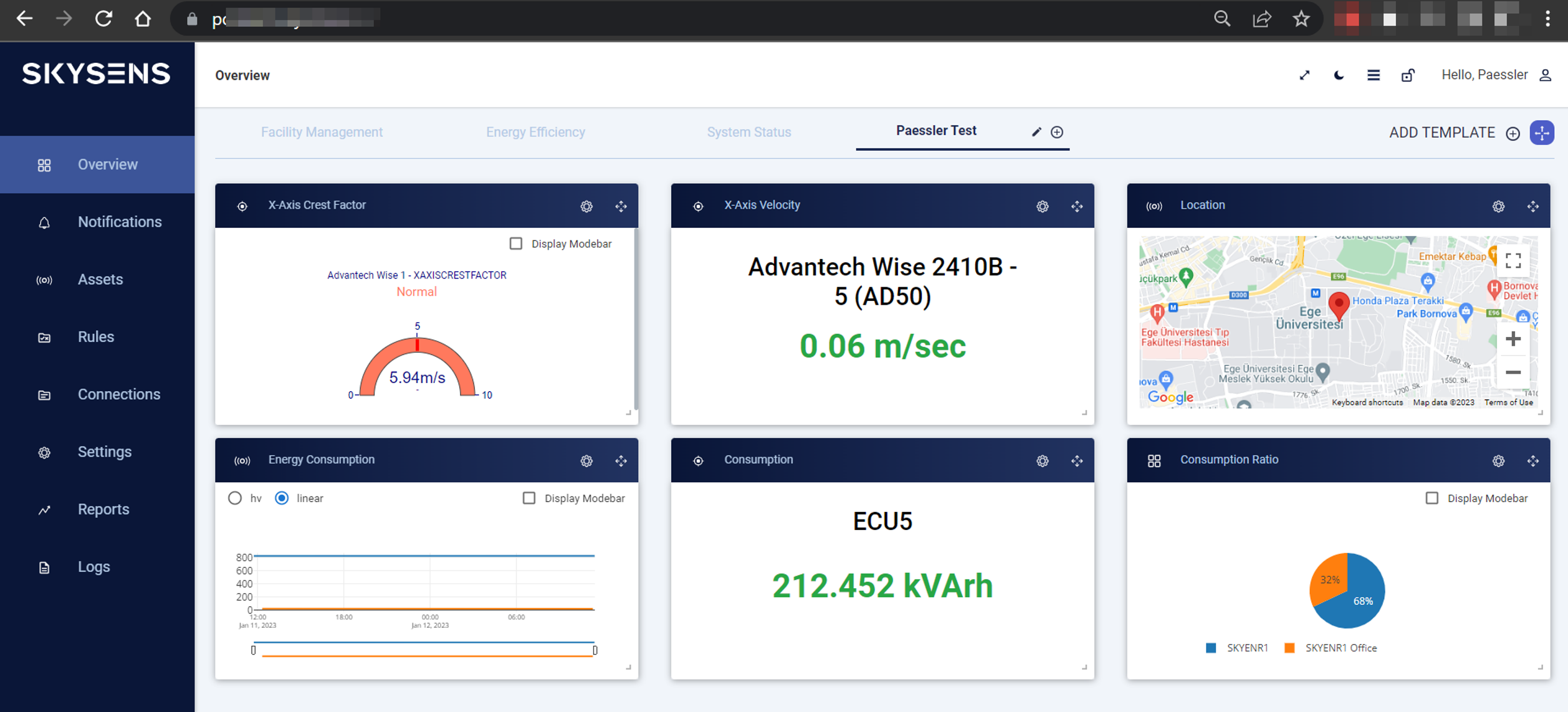

The LPWAN connectivity allows sensor data to be easily, and inexpensively, sent to the Skysens Portal, where it can be analyzed and reported on using fully-customizable dashboards:

The PRTG Bit

The Skysens portal also provides a REST API, which allows PRTG to easily access the data collected by the portal. To use the API, you’ll need to obtain authentication token to validate your requests. This token can then be used by PRTG’s REST Custom V2 sensors – This new sensor type is still in “Beta” status. You must enable “experimental features” in PRTG to access them. As with any pre-release feature, use your own judgement before using them in a production environment. The manual link above will provide more details about the sensor and its status. Similarly, more details about the Skysens API, the available endpoints and the authentication process can be found in the Skysens website.

One thing to note – because the Skysens portal generates a new authentication token whenever a user logs in, the recommendation is to create a unique portal user solely for API use. Administer your devices, dashboards, and so on, using a standard user, and have a second account just to “own” the API key.

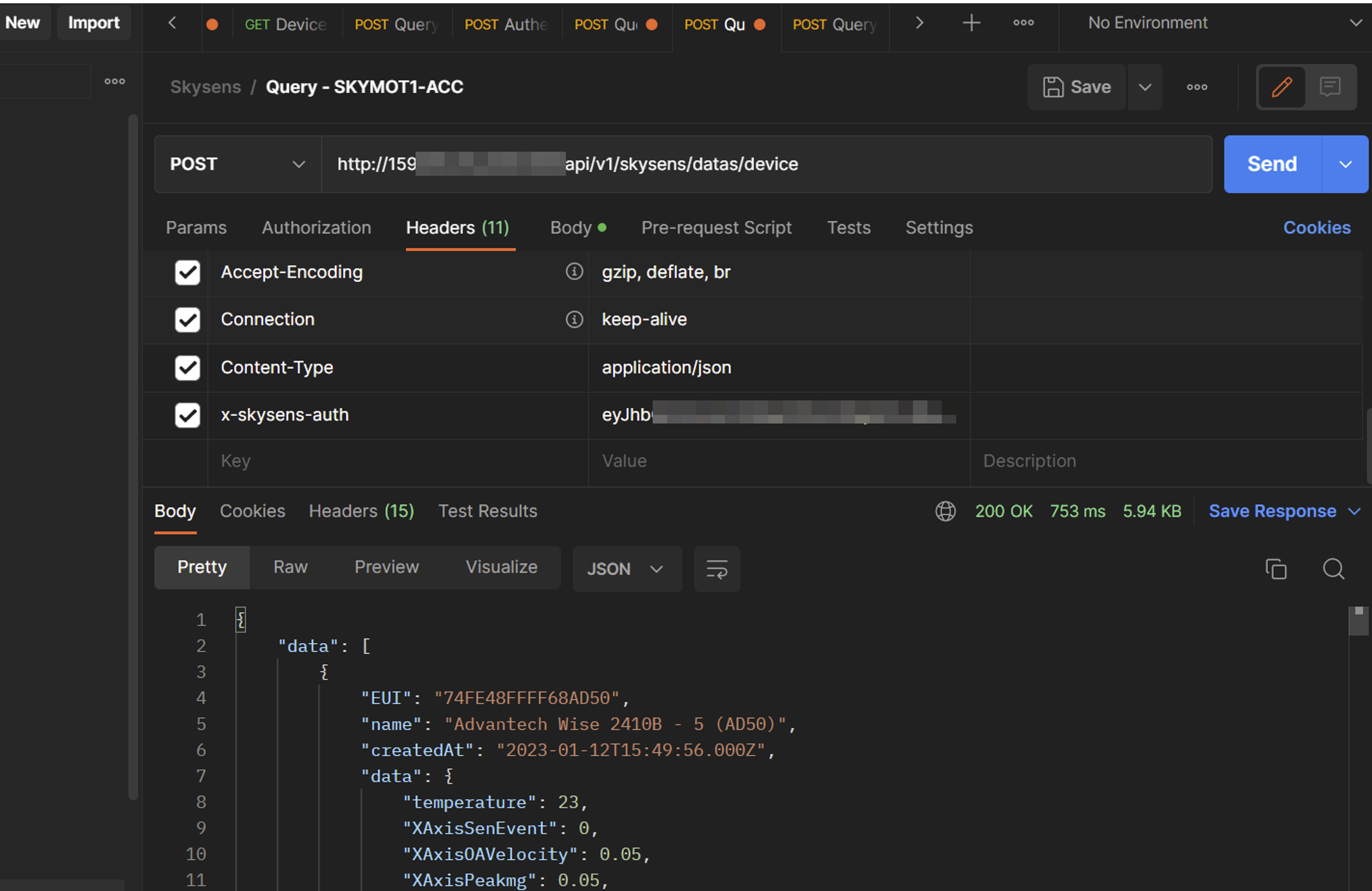

The easiest way to obtain the authentication token and to explore the API endpoints, is to use a tool like Postman :

Once you have obtained the authentication token, you can start building out your sensors:

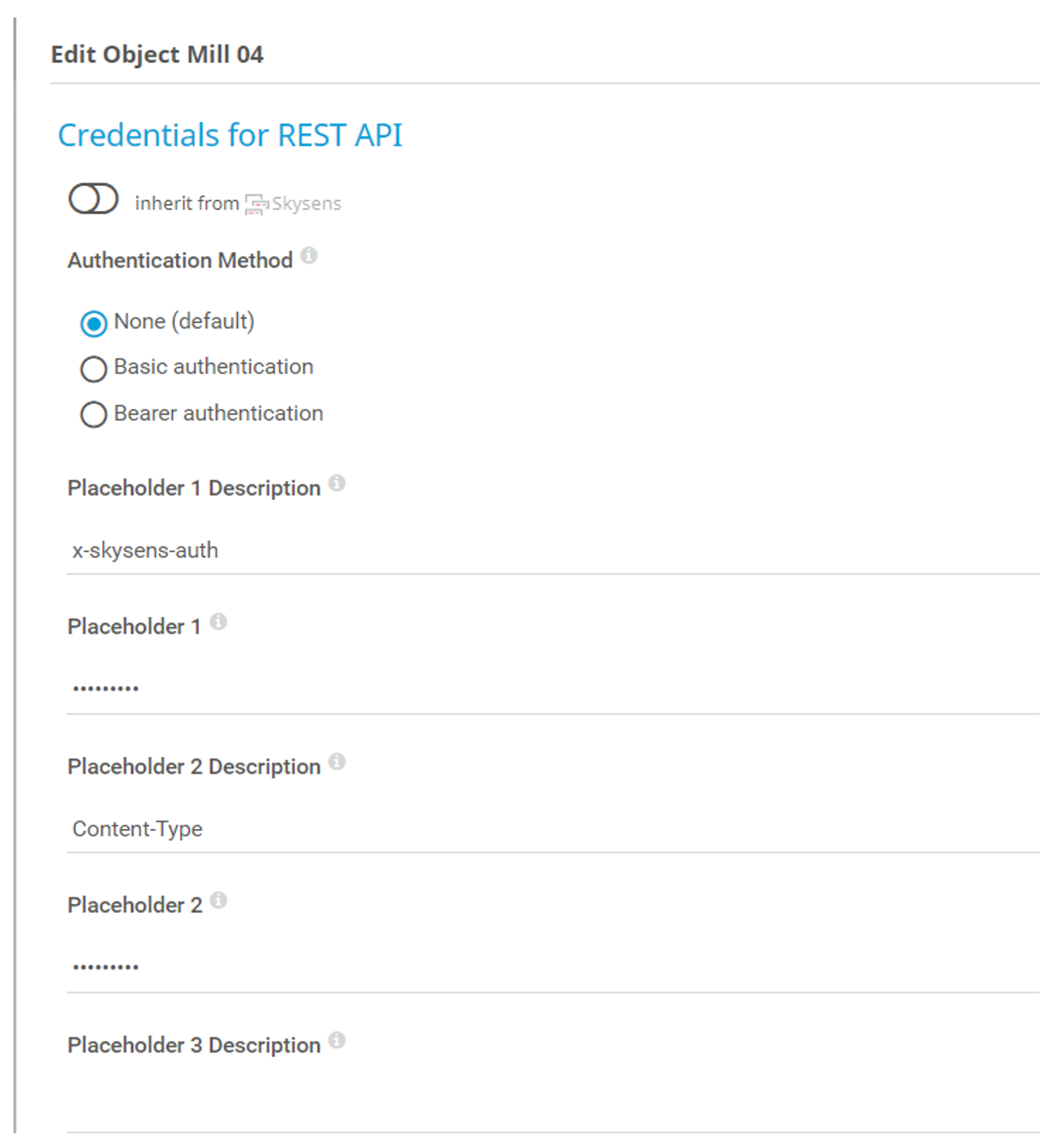

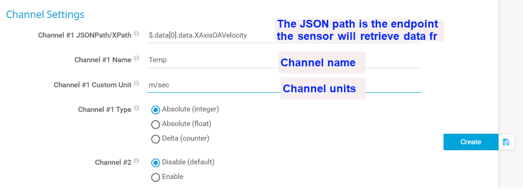

The new REST Custom V2 sensors work slightly differently from the original REST Sensors. Firstly, they don’t need a “template” file to map the API return to a sensor channel, you can just use the JSON Path to the endpoint. The other nice feature is that you can assign API credentials at the “group” or “device” level of the PRTG tree and have those settings inherited by the REST v2 Custom sensors belonging to that group or device. Let’s have a look at how it works.

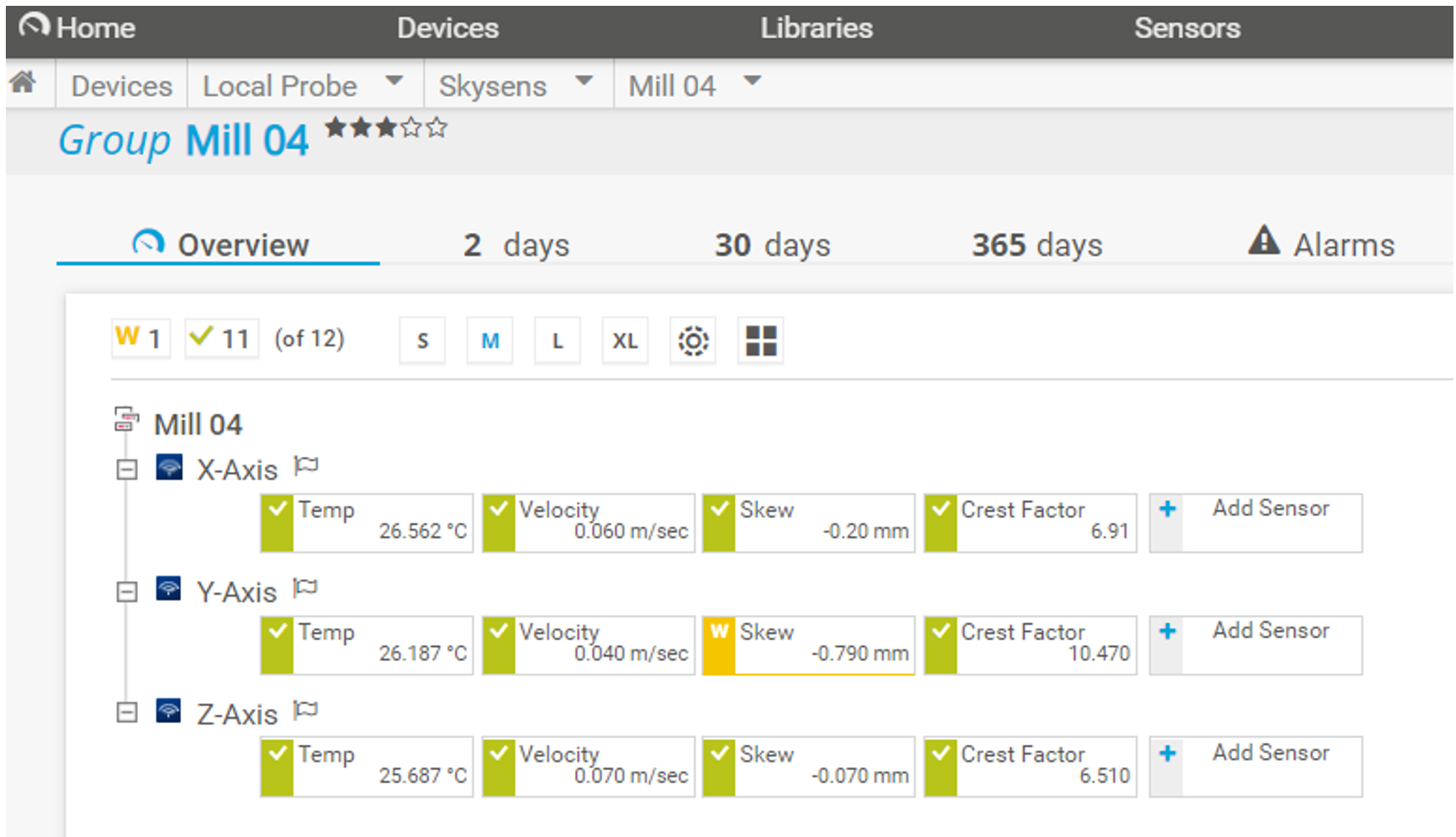

If we look at the settings for the group “Mill 04” in the previous screenshot:

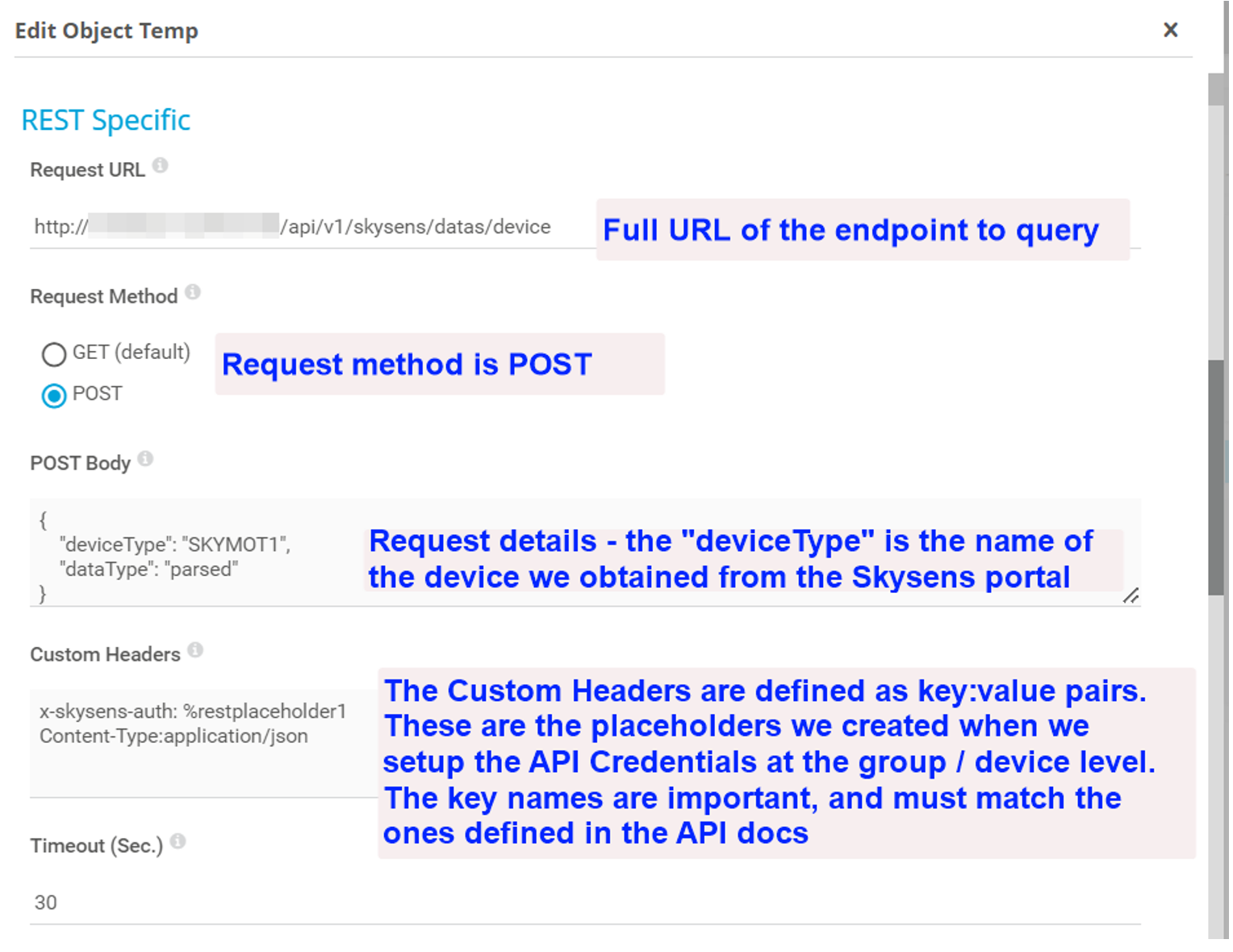

You can see we’ve defined two placeholders. The first, “x-skysens-auth”, stores the authentication token we obtained from Postman. The second, “Content-Type”, holds the value “application/json”. Both are needed by the “Custom Headers” we’ll be defining in our Sensor settings, and are required values, defined in the Skysens API documentation.

Once we’ve set up the credentials at the group or device level of the tree, we can go ahead and start creating the sensors.

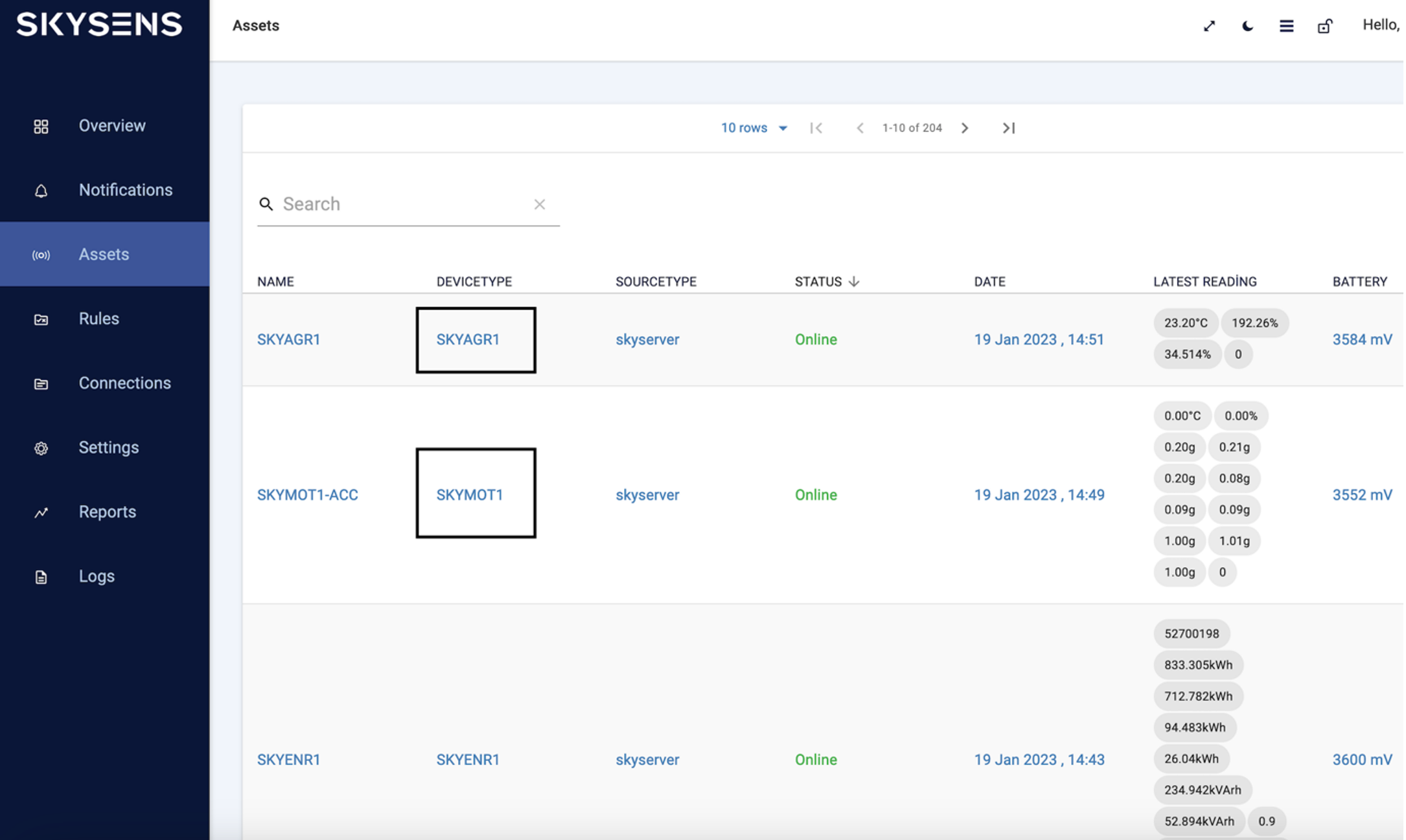

We need one additional piece of information from the Skysens portal, and that’s the type of the physical device (DEVICETYPE) we want to query. You can find this in the Assets tab of the Skysens portal:

Now simply add a REST Custom V2 sensor to the device:

If you need help deciphering the JSON Path, just paste the Postman output into an online tool like JSON Path and it will build the path statement for you.

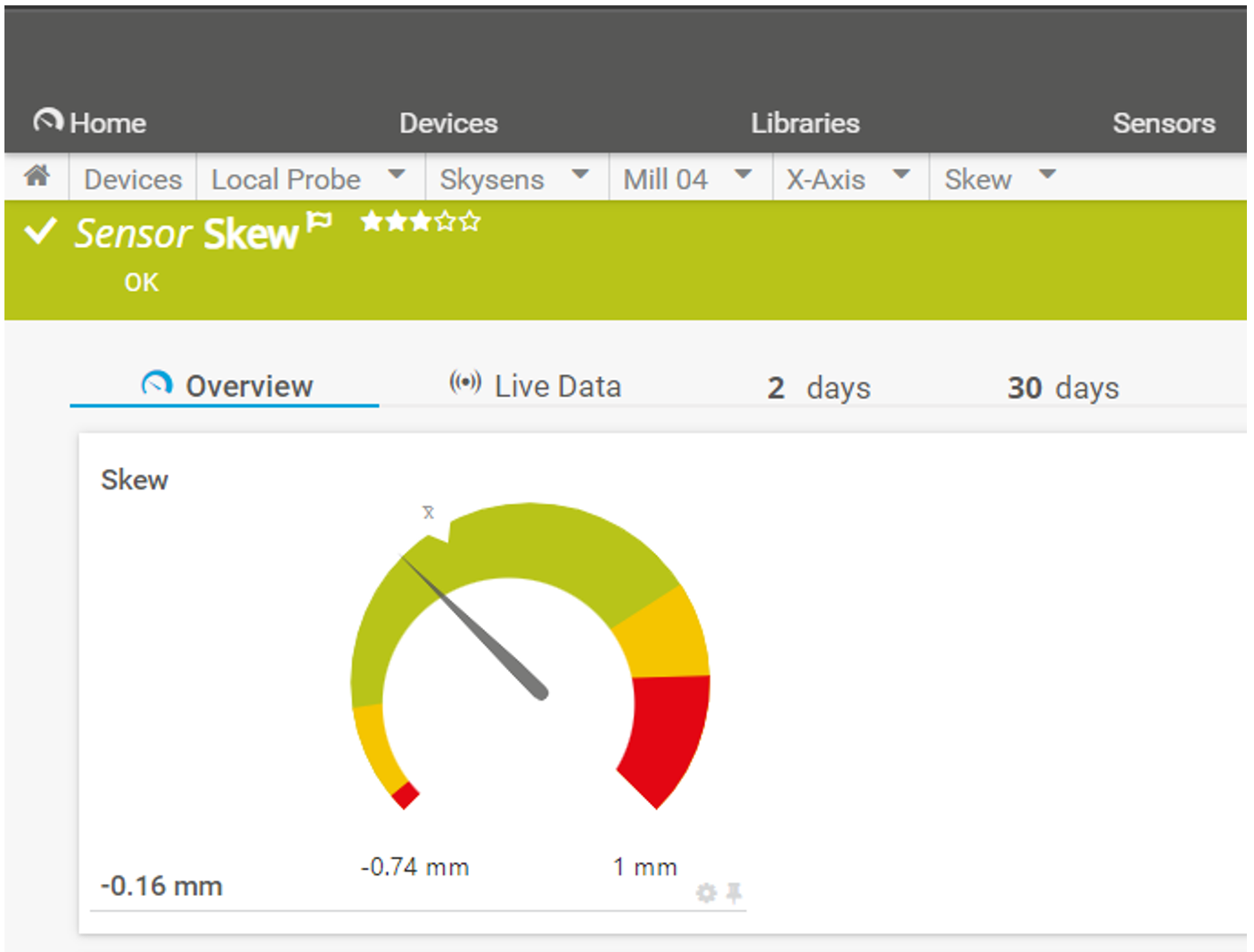

Once the sensors are created, you can add limits (thresholds) to any important channels, to alert you should values fall outside of acceptable limits:

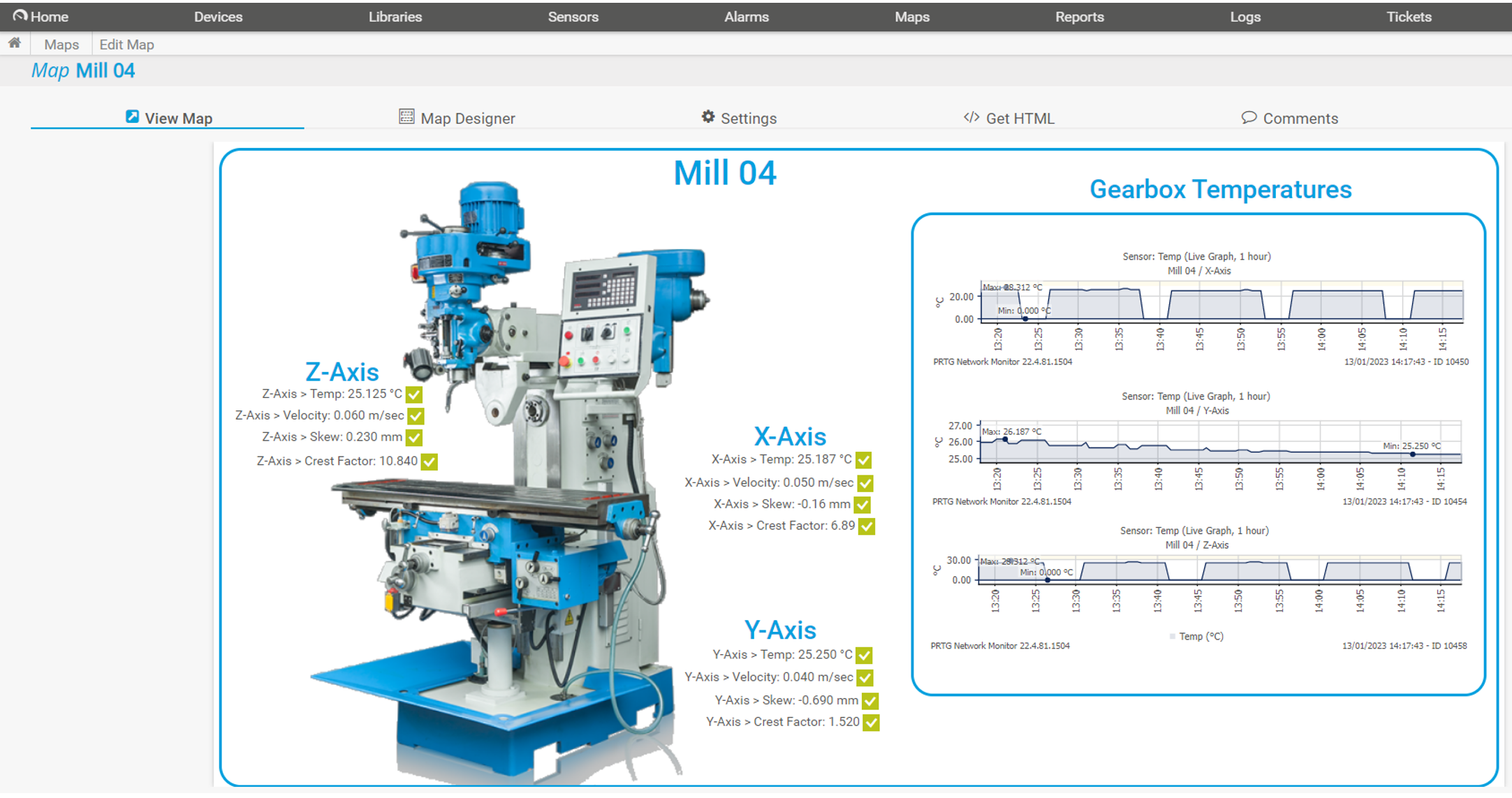

Of course, the sensors can also be added to maps (dashboards) that provide a clear graphical insight into the health and performance of the devices being monitored:

The Skysens solution provides a cost effective, flexible, and easily implemented way to gather, process and analyze health and performance data from legacy plant and machinery, as well as from Smart Building / City / Agriculture environments. Its cloud-based backend enables it to scale as needed – from a couple of sensors in a single building, to enterprise deployments across the globe. The system’s support for multiple protocols and the inclusion of LoRaWAN communications makes it easy for PRTG to retrieve data from the deployed sensors, via the cloud portal. The more you know about your operating environment, the more control you have over it. In the field of IoT and IIoT, knowledge really does equate to power.

Published by

Published by

.jpg)