With so much media and industry attention on ransomware, phishing attacks, and cyber security in general, it can be easily forgotten how important physical security can be for critical IT infrastructure. All the CVE patches in the world are of no use if your servers are stolen, flooded, or incinerated. Ensuring stable and controllable environmental conditions for vital data center equipment is usually the responsibility of the facilities management team. They are the ones who have to make sure that power always gets to where it is needed when it is needed, that cooling and waste heat management is handled as cost effectively as possible, and that physical access to systems is limited to people who have a valid reason.

Controlling and monitoring these complex needs efficiently requires a purpose-built system such as the Computer Multi Control version 3 (CMC III) from Rittal – an intelligent monitoring system that uses physical sensors to ensure control and security for the data center environment.

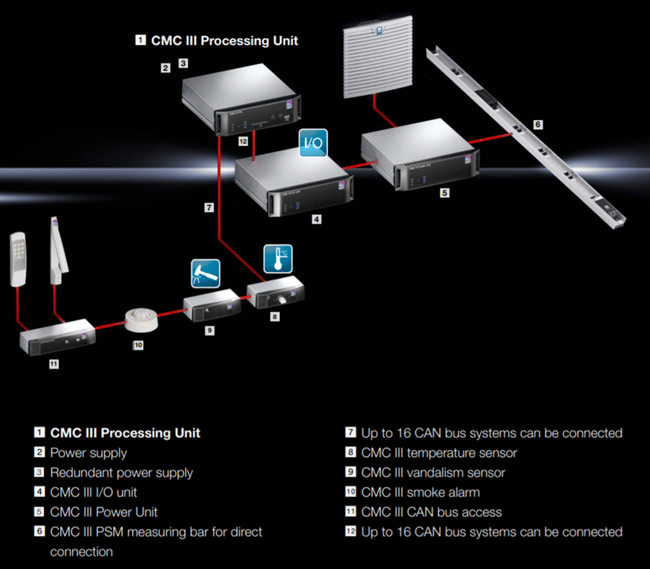

The system comprises a central core “Processing Unit” and multiple, optional sensors:

The system is based on a Controller Area Network or CAN bus topology which simplifies installation and cabling. Up to 34 sensors can be connected to a single processing unit, and these cover a wide variety of metrics such as:

- Temperature & humidity

- Vandalism / acceleration

- Differential pressure

- Liquid / leakage

- IR Door & side panel opening

- Airflow

- Smoke detection

In addition to these passive sensors, the system can also be enhanced with “I/O Units” containing switchable relays, and “Power Units” to monitor voltage, current power, and frequency of electrical systems, and activate ancillary systems such as cooling fans.

Furthermore, CMC III also provides enclosure access control and can manage and monitor both keypad and RFID based access to cabinets.

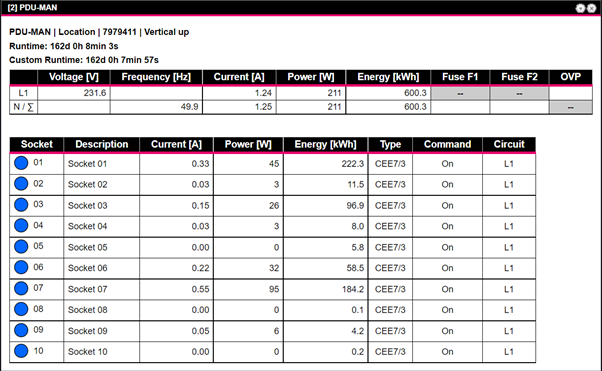

The collection of data is only the basis. The benefit of the data for the user is that it provides them with an overview and transparency. CMC III Processing Unit includes a built-in web server for aggregating data and producing charts and reports. This dashboard shows the stats for a connected PDU for instance:

Paessler PRTG – Not just for IT admins

More interestingly from the Paessler PRTG perspective, the system also allows access to the collected data using SNMP, OPC-UA and Modbus TCP. Configuration of all these services in the CMC control panel is very simple. Once that is done, you can simply use whichever PRTG sensors you prefer.

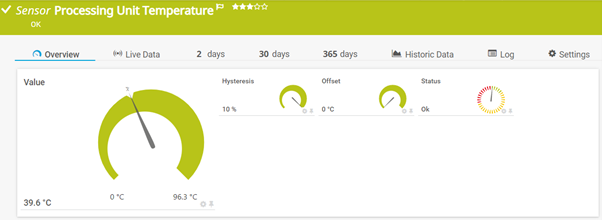

Here is an example of an SNMP Custom Advanced sensor showing the temperature of the Processing Unit:

One cool feature (sorry!) worth noting is that Rittal has included an OID for the “hysteresis” value of the sensor. Hysteresis is a physics term that refers to the delay which may occur between a change in state of a physical property, and the detection or measurement of that change. The higher the value, the further the returned value is from “real time”.

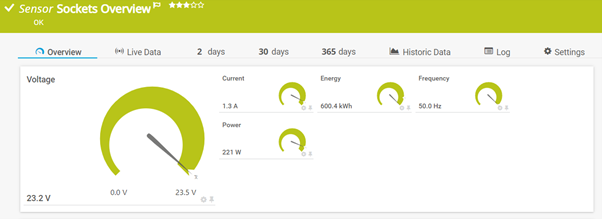

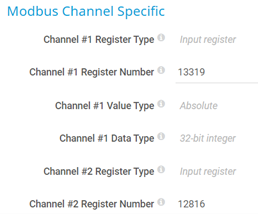

As another example, we are using a Modbus TCP Custom sensor to retrieve overview statistics from a Rittal Power Distribution Unit (PDU):

The sensor is easy to configure, just needing the Modbus “register”, where the desired data value is stored:

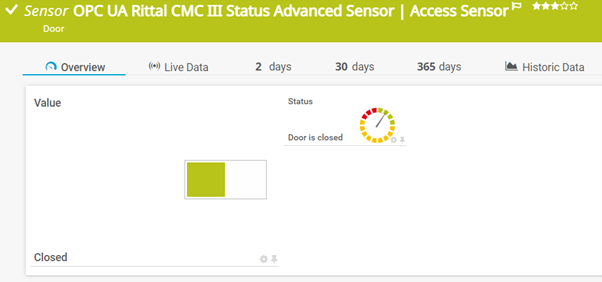

Another custom sensor type that can be used with the CMC III is the OPC UA Custom sensor. Here, we use it to detect the state of the enclosure door:

As with every PRTG sensor, thresholds (limits) can be assigned to any of the defined sensors, regardless of the source protocol. When those thresholds are exceeded, e.g. due to an open enclosure door, an alert can be sent to nominated users.

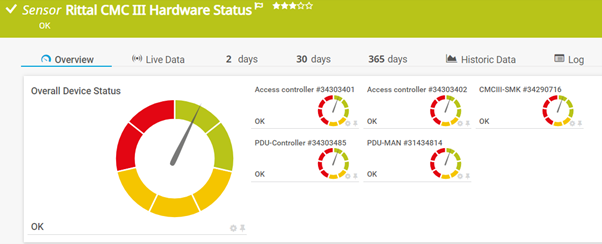

Of course, it is great to have the CMC III and its sophisticated physical sensors monitoring the data center and letting the facilities team know when something is amiss. Nevertheless, that makes the CMC III itself a critical piece of infrastructure. So, what happens in the unlikely event that it has a problem? With that in mind, we have developed the out-of-the-box sensor SNMP Rittal CMC III Hardware Status with our product partner Rittal, specifically for monitoring the health and performance of the CMC III hardware.

The sensor shows the status of the CMC III Controller and all attached sensors and modules:

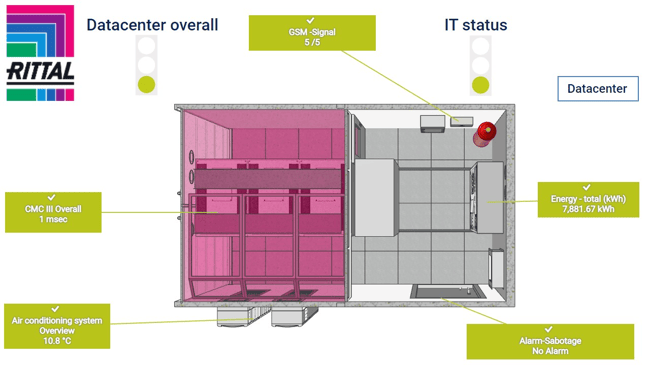

IT Admins all over the world have been benefiting from unrivaled PRTG's collection, aggregation, alerting and reporting of health and performance data for decades. Now, the data center facilities management team can get the same benefits by combining Rittal’s CMC III and PRTG to monitor the vital services that make sure all the IT kit can function as intended. They can even have their own cool dashboards too:

Central control with Rittal and PRTG

With the help of the predefined SNMP Rittal CMC III Hardware Status sensor, PRTG detects existing CMC III devices and the associated sensors in the network via auto-discovery and automatically integrates them into the central monitoring. With PRTG Custom Sensors, the measured values of the sensors and thus the entire data center environment can be integrated into PRTG via different protocols. The networked use of Paessler PRTG and Rittal CMC III thus offers a whole range of significant benefits from this product partnership.

Published by

Published by