If you’ve been following our blog over the past few years (and if you haven’t been, you really should), you will know that we have implemented many features in our Paessler PRTG monitoring software that help you monitor infrastructure in industrial environments. In fact, we’ve added so much functionality that you might have lost the overview. So here’s a summary of the sensors we’ve added for monitoring OT, IIoT and IT in factories and plants.

In the video below, Felix, a Business Development Manager here at Paessler, gives you a tutorial of the industrial capabilities of PRTG; watch the video, or read on below for a closer look at the sensors he covered.

Before we get to the industrial sensors in PRTG, it makes sense that we first explain what a sensor is.

i What are PRTG sensors? Think of them as data collectors that collect information from devices. This data can be used to trigger alerts and notifications when values exceed defined thresholds. Sensors can be displayed in PRTG to show you if there is an issue with the monitored device, and they can show you data like recently measured values, minimum values, maximum values, values over time, and more.

Now let’s take a look at the industrial IT sensors that PRTG provides you with. Here’s what we will be covering:

- Modbus TCP Custom sensor

- OPC UA sensors

- Beckhoff IPC System Health sensor

- MQTT sensors

Modbus TCP Custom sensor

For IT professionals in factories and plants who are maintaining traditional network elements and industry-specific infrastructure, Modbus TCP devices often contain important information needed for monitoring the entire infrastructure. The Modbus TCP Custom sensor in PRTG lets you retrieve a maximum of 5 metrics from a Modbus TCP device.

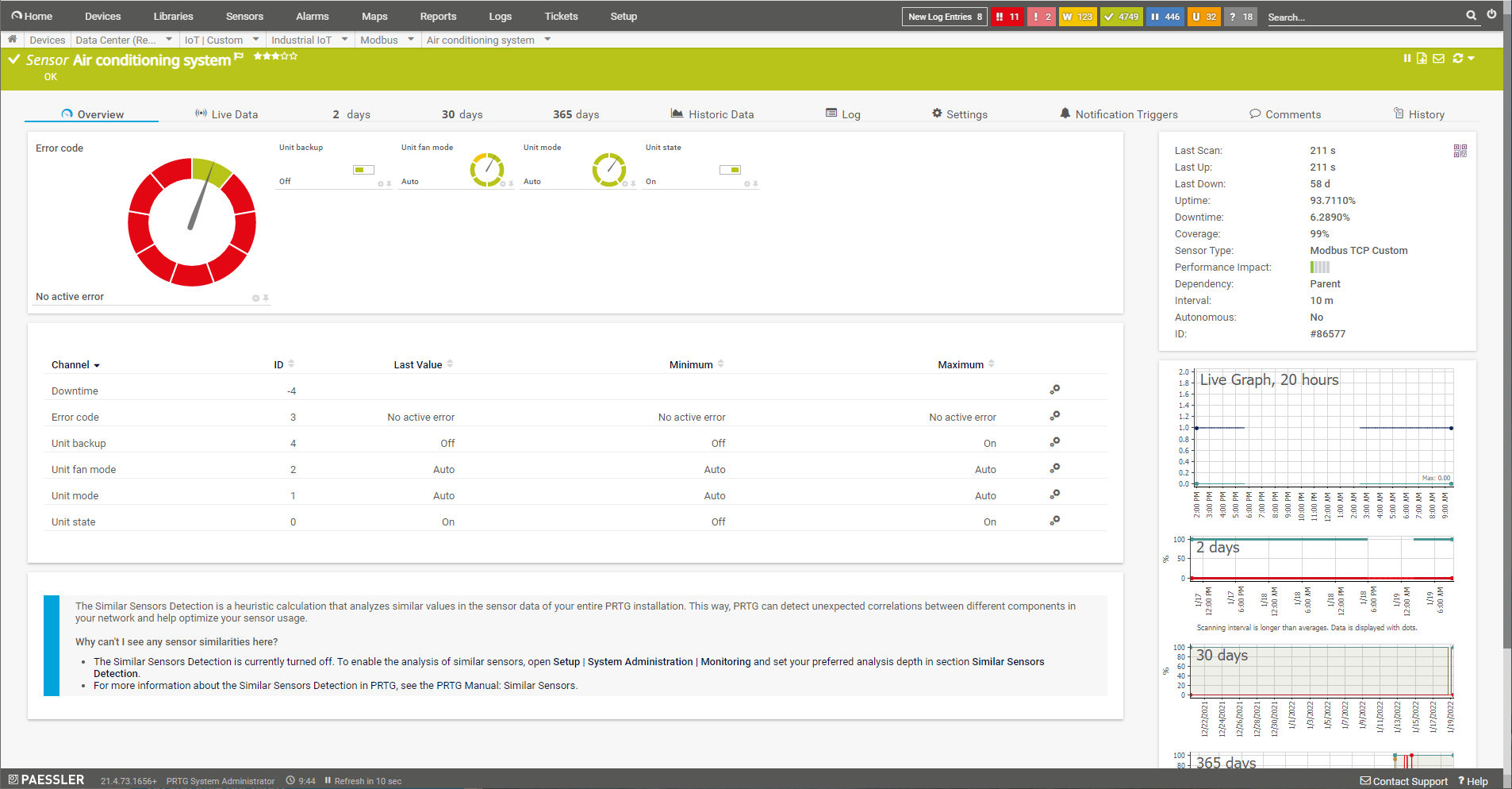

A great use case for this is monitoring an air conditioning unit:

This shows you that there is no active error. We’re measuring the fan motor, the set temperature of the air conditioner, as well the current temperature of the air conditioner.

And, if you have Modbus RTU devices, PRTG also has a sensor for those, too.

OPC UA sensors

Due to the importance of OPC UA as a standard in many industrial environments, it makes sense that PRTG offers functionality to utilize OPC UA to monitor industrial infrastructure. We offer three OPC UA sensors, and here’s a short description and example for each one.

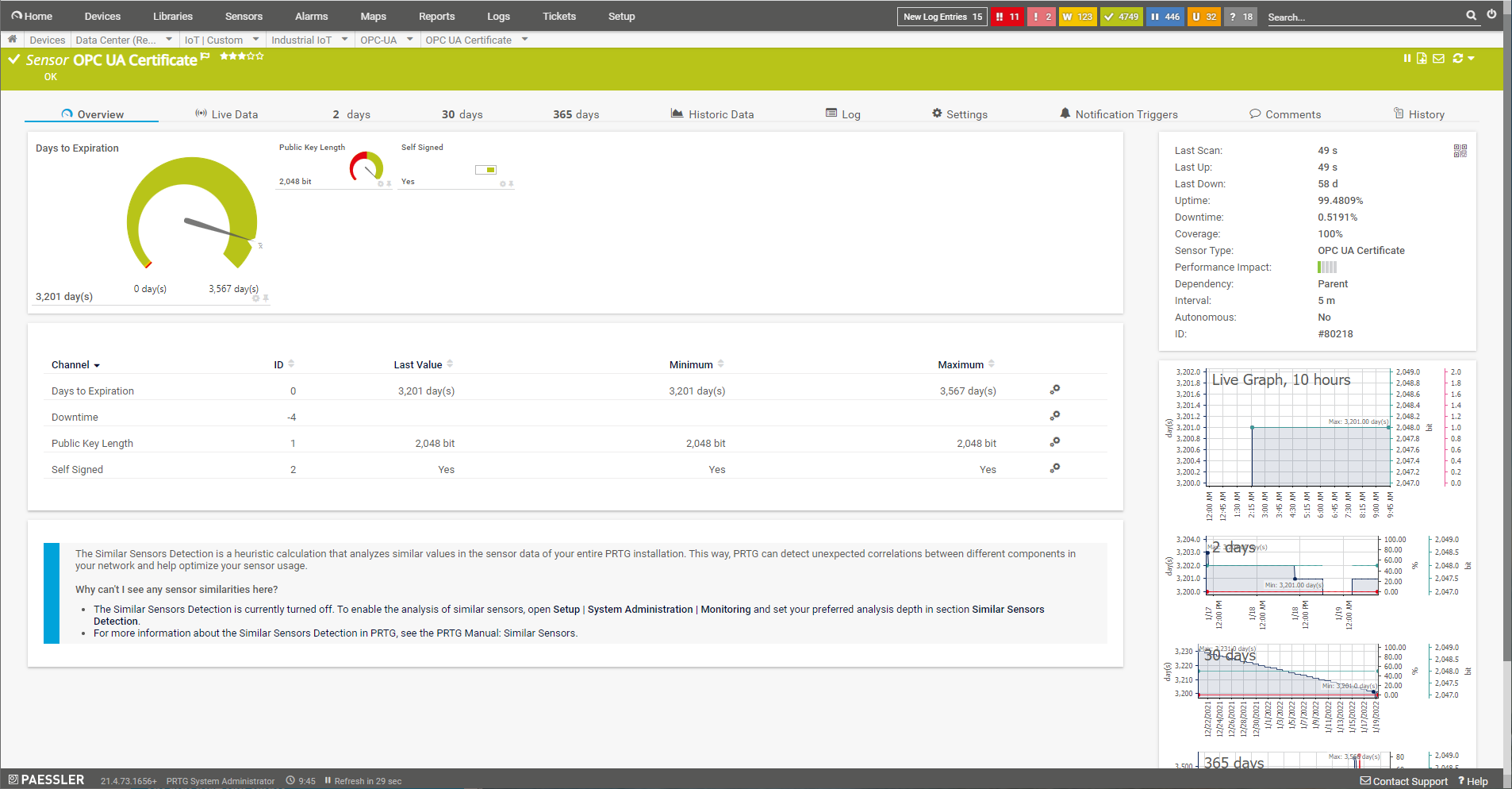

OPC UA Certificate sensor

This sensor ensures that the OPC UA certificates in your environment don’t expire. I’ve written more about why this is important in a separate post, but the point of it is: if the certificates expire, OPC UA communication in your environment will be negatively affected. The OPC UA Certificate sensor of PRTG shows you the number of days until expiration of your certificates, as well as other details, such as whether the certificate is self-signed, and the public key length.

In the event that a certificate has expired, PRTG will display an alert status and can be configured to send you a notification.

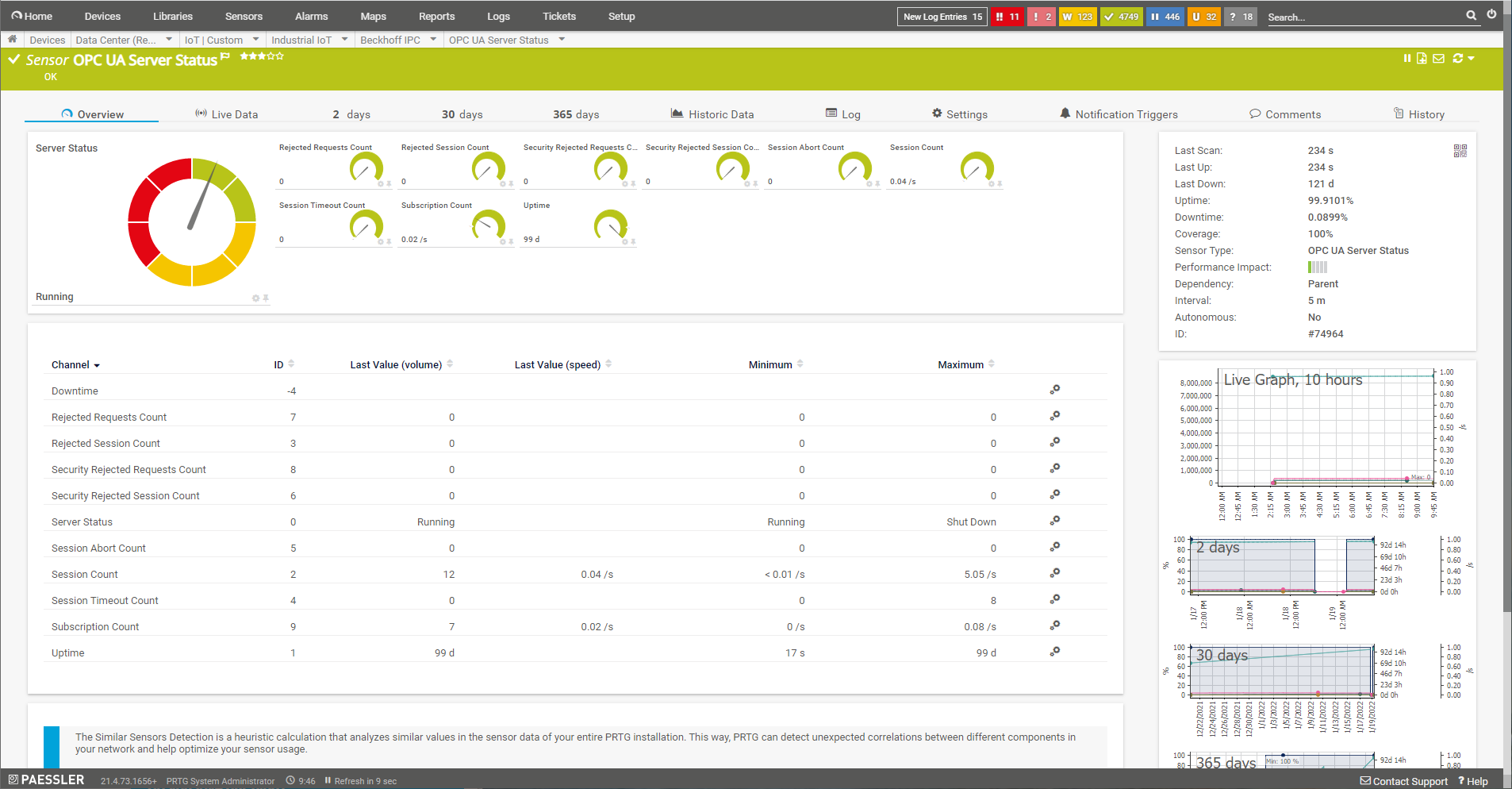

OPC UA Server Status sensor

The OPC UA Server Status sensor lets you check several metrics of an OPC UA server, including whether it is up, the session count, the number of rejected sessions, and more:

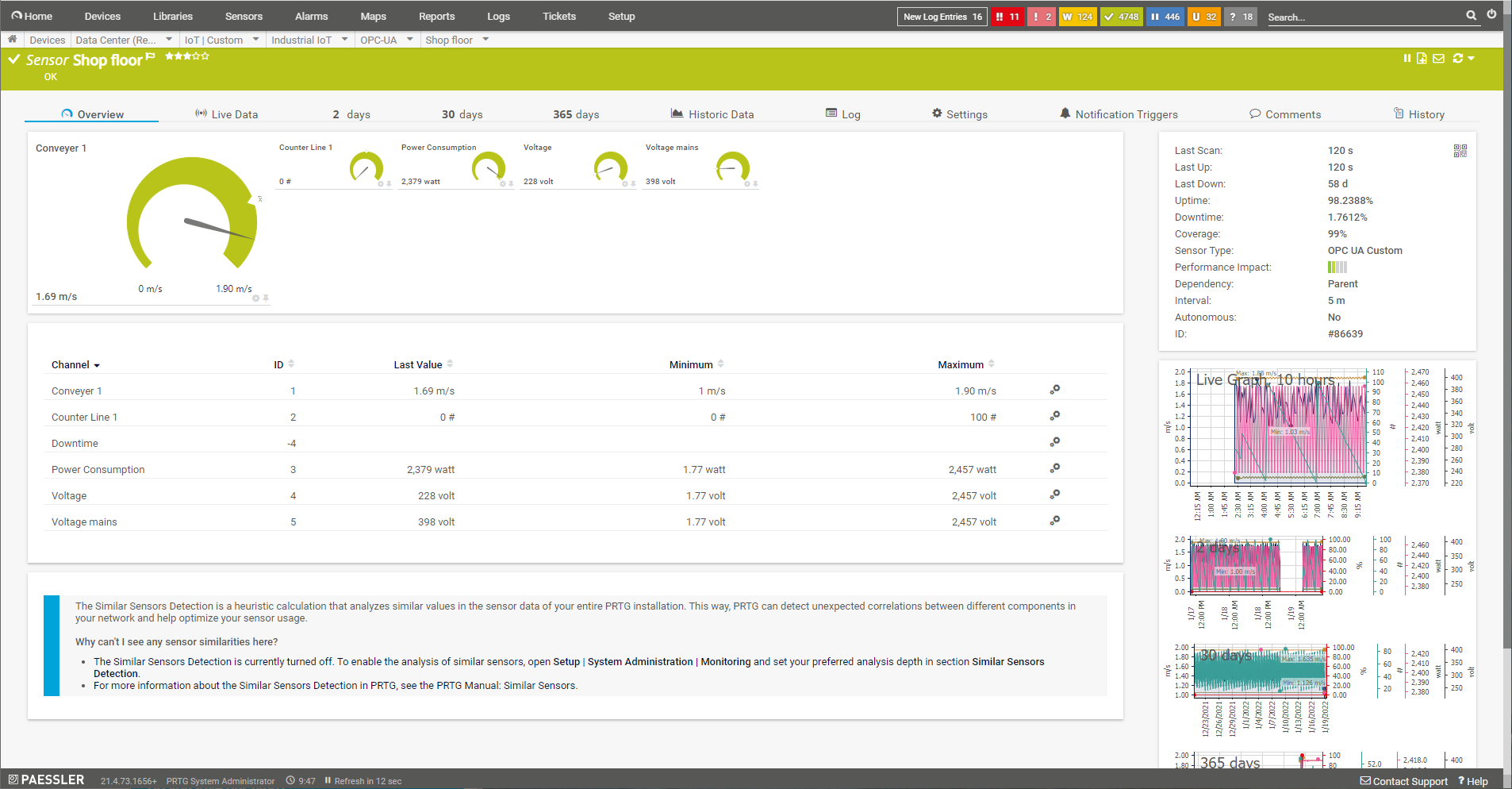

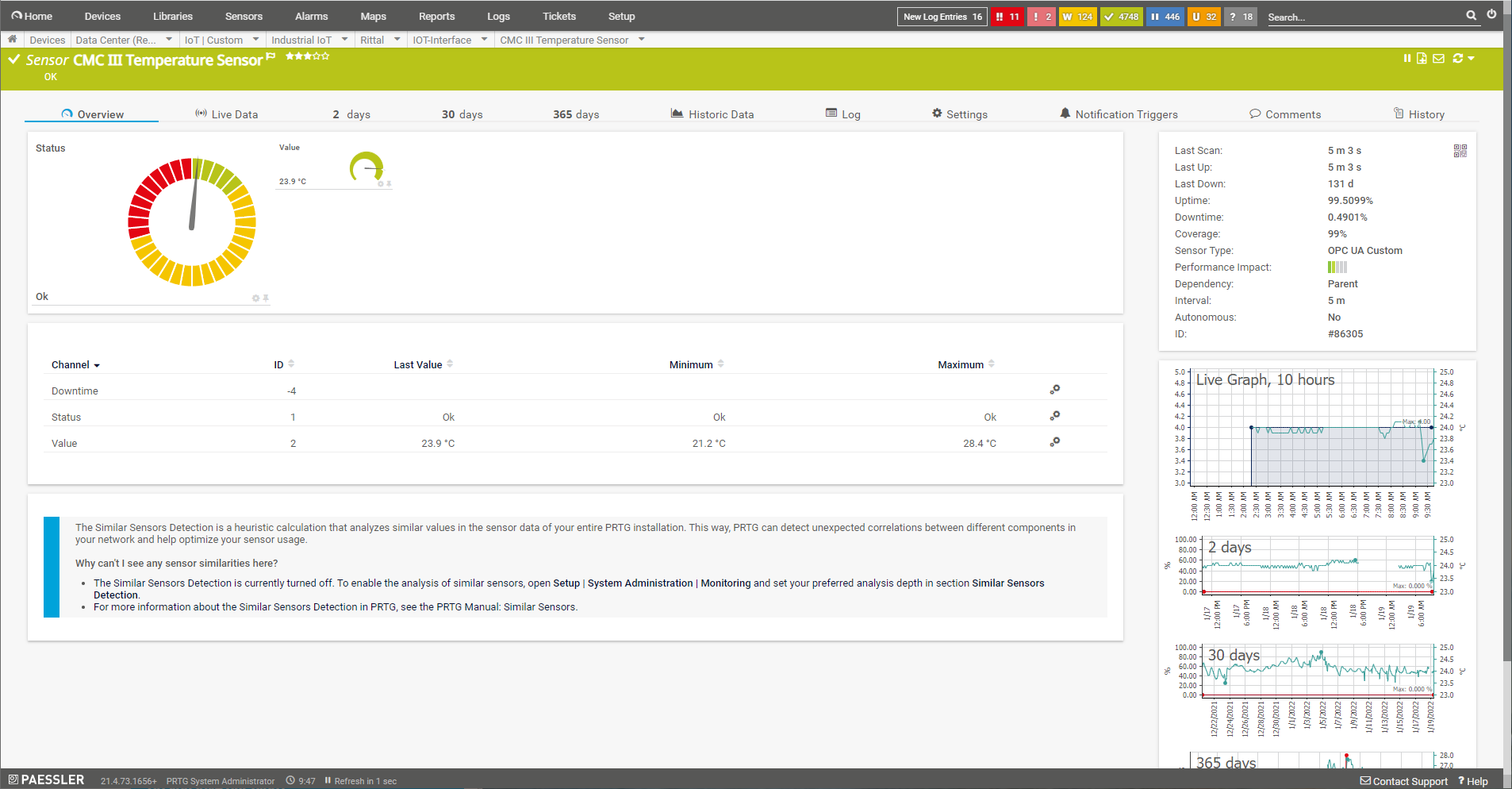

OPC UA Custom Sensor

The OPC UA Custom sensor gives you the flexibility to get more information about the factory floor from an OPC UA server. Here’s an example where we retrieve the conveyor belt speed, power consumption, and voltage of a machine on the factory floor from an OPC UA server.

Another example of this is obtaining the temperature of an industrial enclosure through a Rittal interface.

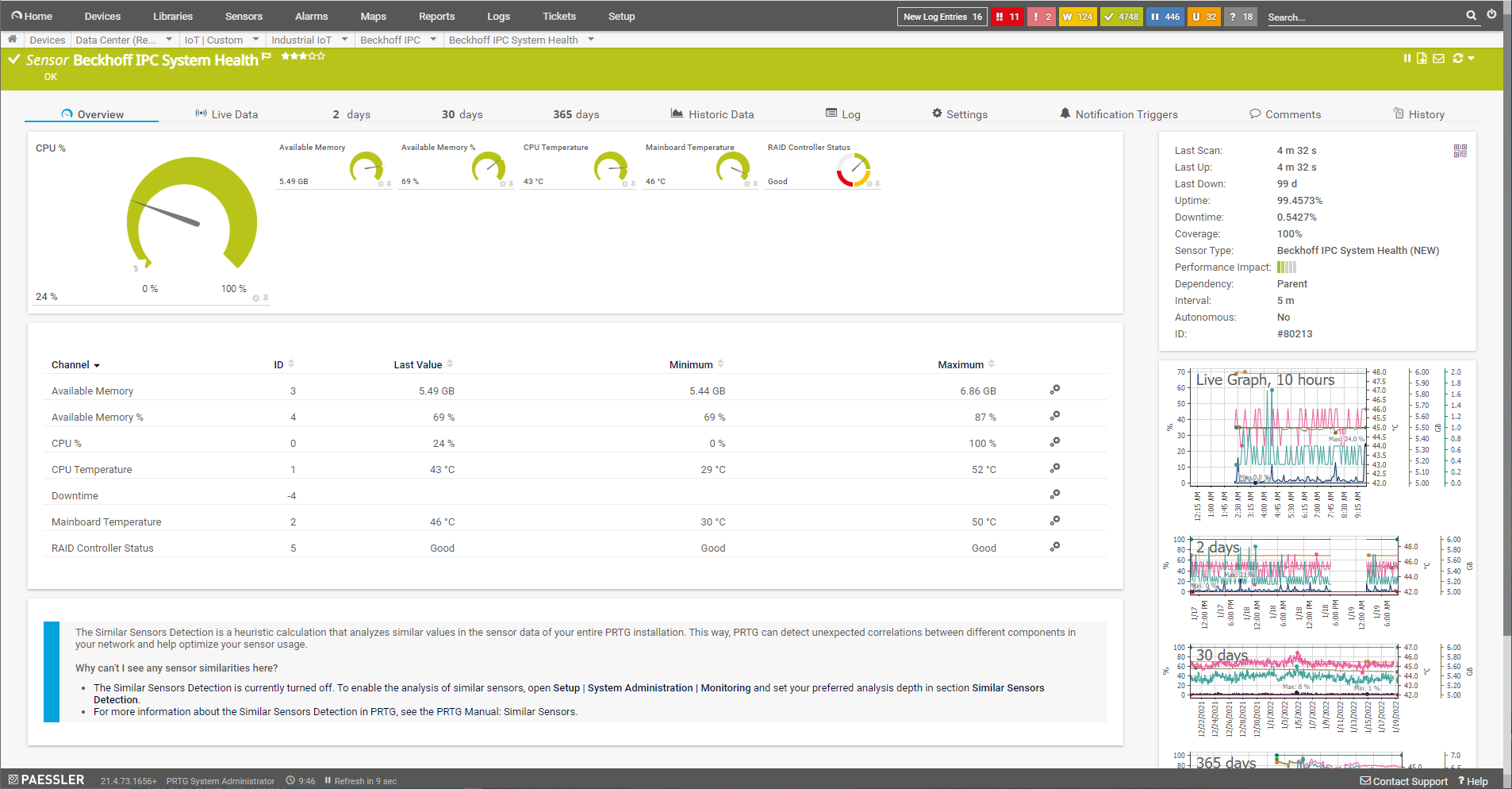

Beckhoff IPC system health sensor

The Beckhoff IPC System Health sensor lets you monitor the health of Beckhoff IPC devices, which are commonly found in industrial environments. You can monitor metrics like the device’s available memory, the CPU usage, the temperature of the mainboard, and the RAID controller status.

Read this blog post for more information about the Beckhoff IPC server sensors.

MQTT sensors

The MQTT protocol has become more commonplace in industrial implementations, thanks to the Industrial Internet of Things. PRTG provides three sensors to help you monitor devices connected through MQTT as well as the status of your MQTT installation.

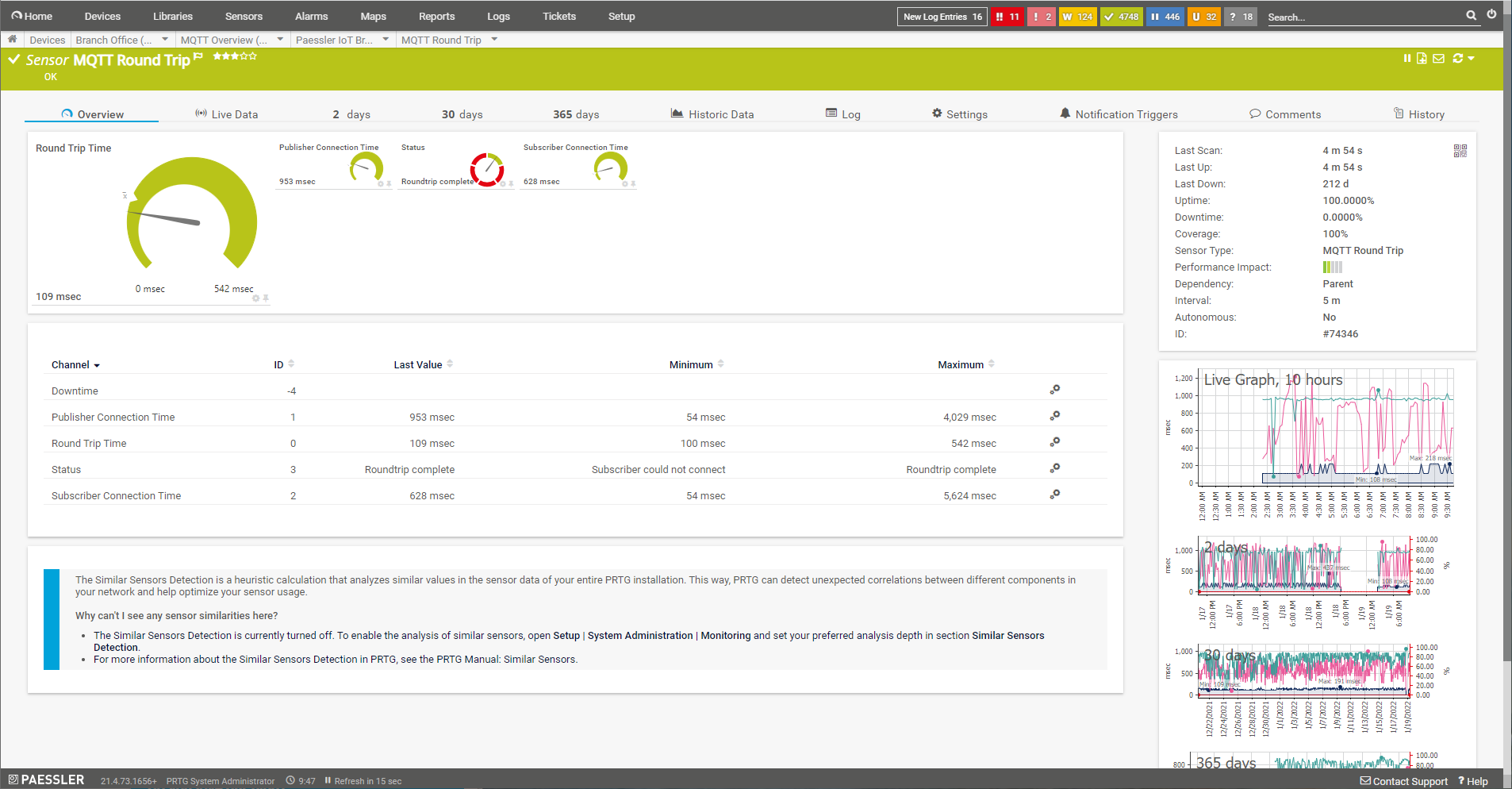

MQTT Round Trip sensor

The MQTT broker is crucial to MQTT communication, and so it’s important to monitor. The MQTT Round Trip sensor does just this by sending a packet to the broker, and then requesting the packet again to ascertain whether the broker is sending and receiving messages, and how long the communication takes.

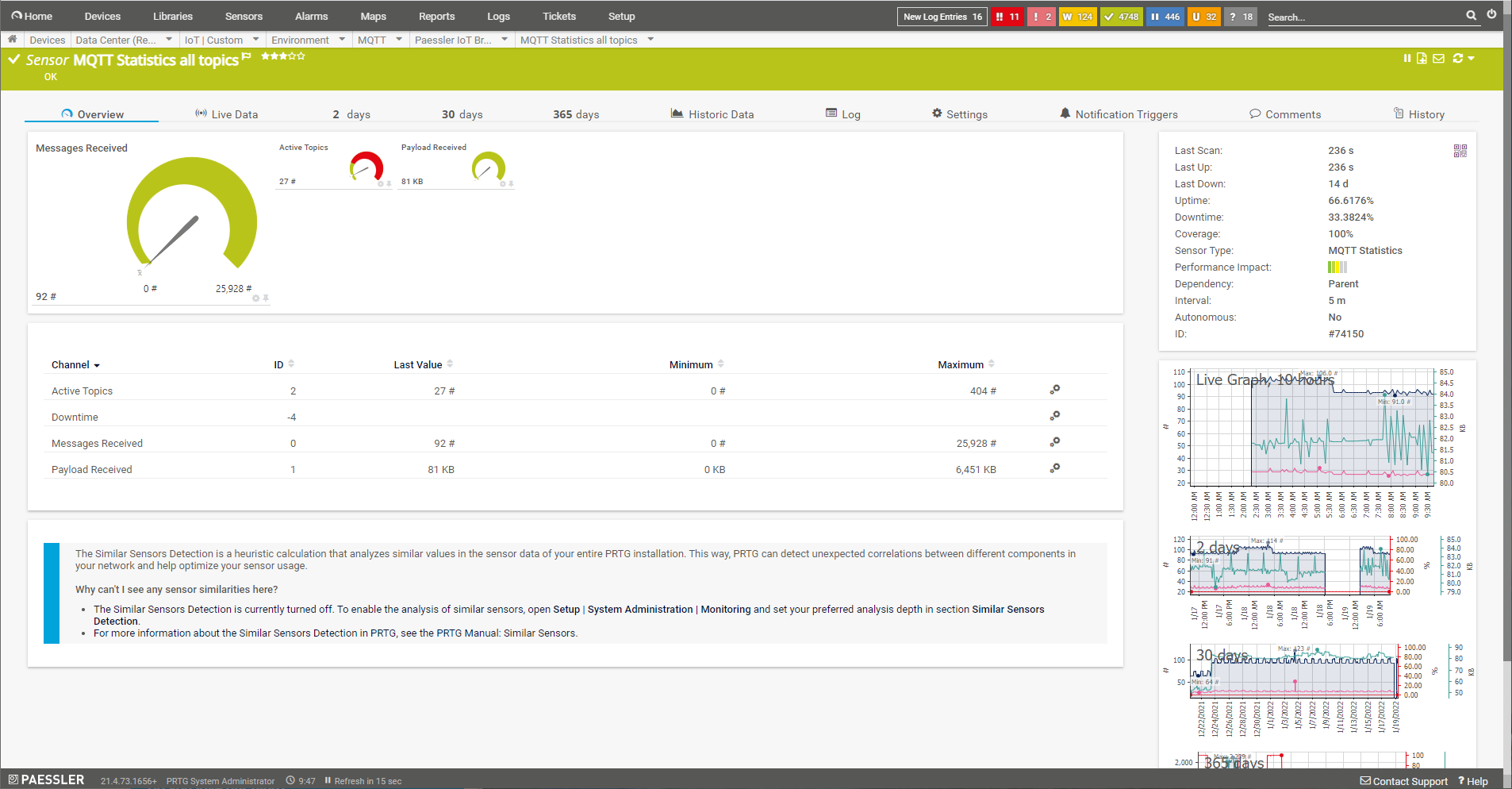

MQTT Statistics sensor

Using the MQTT Statistics sensor, you can get statistics for either a specific MQTT topic, or all MQTT topics. Metrics possible are the number active topics, the number of messages received, and the size of the payload received. This is important to understand if the broker and IIoT devices are working properly.

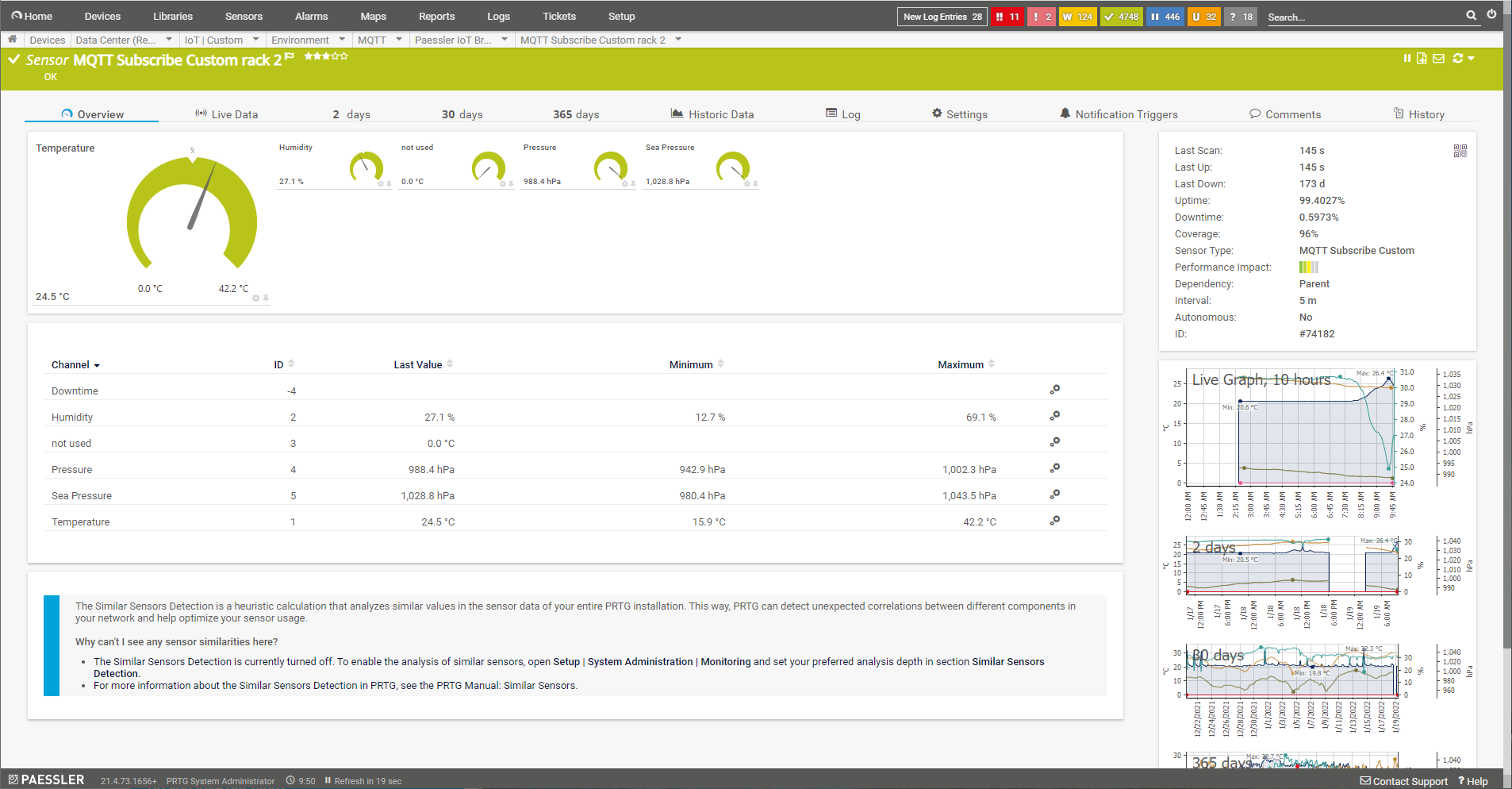

MQTT Subscribe Custom sensor

The MQTT Subscribe Custom sensor lets you get data from a specific MQTT topic. The data available depends on what the IIoT device provides. In the example below, we’re able to retrieve environmental data from a device – specifically humidity, air pressure, and temperature.

Combining sensor data into dashboards

One of the advantages collecting data from IT, OT and IIoT devices is the ability to put it all into dashboards, so that the right teams see the right information. Felix shows you some great examples of industrial IT dashboards in the video above, some of which I’ve also written about:

To learn about our industrial IT functionality, visit our industrial IT information page, and make sure you subscribe to our blog for the latest in industrial monitoring!

Published by

Published by