When I first started learning about industrial systems and architecture a few years ago, one of the first terms I bumped into was “SCADA” – short for “Supervisory Control and Data Acquisition”. There’s a reason for this: SCADA systems are central to just about any OT environment. Because of how important they are to industrial infrastructure, it’s vital that they are up and operating as they should be. Let’s take a look at what SCADA systems do, and how to ensure that they are functioning as expected.

What is SCADA?

Supervisory Control and Data Acquisition systems are made up of software and hardware components that are used to supervise and control industrial processes. SCADA systems monitor data in real-time and give users a human-machine interface (HMI) for providing process commands to components such as control valves, actuators, motors, and more. They are crucial for industrial organizations since they help to maintain efficiency, process data for smarter decisions, and communicate system issues to help mitigate downtime.

SCADA systems are used by a wide variety of companies and organizations. They can be implemented to monitor and control power grids, water treatment plants, processes on a production floor, and more. Metrics that are monitored include everything from pressure, power utilization and production time through to facility processes like heating, ventilation, and HVAC systems of buildings.

To understand where in the OT picture SCADA systems operate in industrial IT architecture, it helps to consider the automation pyramid:

SCADA systems form part of the process control layer. They are connected to the Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs) of the control level, which in turn gather data from sensors and devices in a plant – the field level. This gathered data can be used for automated responses, such as reducing pressure in a system when it gets too high, as well as for gaining insights into the production process and for triggering alarms when there is a failure.

Integrating your SCADA system into your monitoring concept

With such a central role in OT, it’s imperative that the SCADA system is always operational. This means monitoring its status constantly. But bringing SCADA into your monitoring concept also has other benefits, especially due to the convergence of IT and OT.

Let's look at some of the results of integrating SCADA into your monitoring.

Monitor the SCADA server

Just like with any other system, a SCADA system is only as good as the hardware it's running on, and so this needs to be constantly evaluated for errors or potential errors. This includes metrics such as CPU load, memory usage, storage space, performance, and more. By getting alerts when threshold values you define are exceeded, you can immediately know if there is a problem.

Additional alarms

While a SCADA system already provides you with alarms when things go wrong, monitoring software can add even more alarms to ensure that nothing gets missed, such as warnings about the servers that the SCADA system runs on. If the monitoring tool provides alert functionality, you can set thresholds so you’re alerted when conditions deviate from what is considered “normal”.

Getting the full picture

IT and OT convergence means you need to get an overview of all aspects of your industrial infrastructure. This entails getting OT, IT, and IIoT in one place. In addition to OT metrics collected by SCADA systems, there are many other data points that are important for understanding an industrial environment. For example: the health of switches (including metrics like port status and packet loss), the status of your UPS, the memory, CPU and RAM usage of industrial PCs, the health of industrial gateways, the status of common IT devices like printers, servers, and much more.

Paessler PRTG and SCADA systems

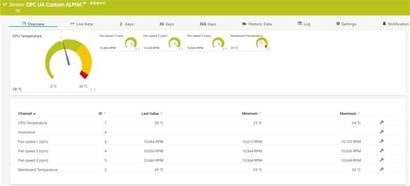

Paessler PRTG is monitoring software that can monitor IT, OT and IIoT elements of your industrial infrastructure. OT devices and systems, industrial Ethernet devices, industrial gateways, IIoT sensors and devices, traditional IT hardware: PRTG understands it all. It also works well together with SCADA systems.

An example: PRTG helps you to keep an eye on the hardware supporting your SCADA system. This includes the storage, memory usage, CPU performance, and more. In addition, it lets you add even more alarms to your monitoring to ensure that nothing in your infrastructure gets missed. PRTG gives you the ability to set thresholds so you’re alerted when conditions deviate from what is considered “normal”, and you can define notifications with targeted escalation using various mechanisms, like push messages, emails, and more.

An example: PRTG helps you to keep an eye on the hardware supporting your SCADA system. This includes the storage, memory usage, CPU performance, and more. In addition, it lets you add even more alarms to your monitoring to ensure that nothing in your infrastructure gets missed. PRTG gives you the ability to set thresholds so you’re alerted when conditions deviate from what is considered “normal”, and you can define notifications with targeted escalation using various mechanisms, like push messages, emails, and more.

Speaking of notifications, we also recently added functionality for PRTG to send notifications as OPC UA tags to your SCADA system. This lets you bring notifications from other areas into your SCADA view, if your SCADA system has an OPC UA server.

If you have any questions about monitoring SCADA systems, or about PRTG in industrial environments, let us know in the comments below!

Published by

Published by