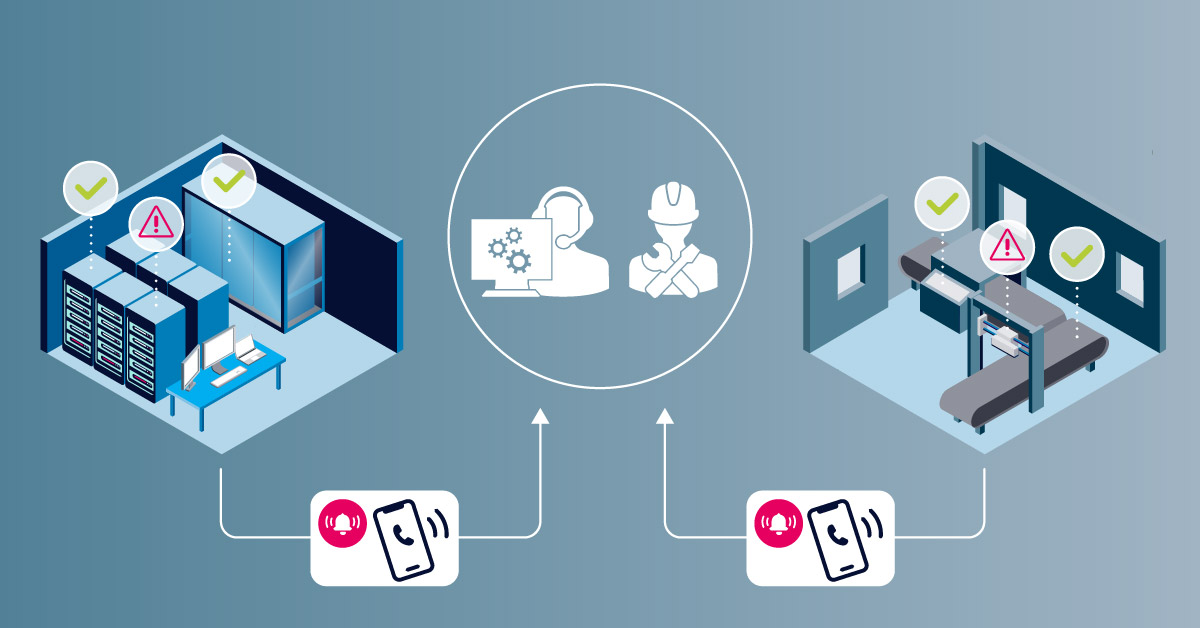

IT and production are becoming increasingly interconnected. This creates more complexity – both in terms of infrastructure itself and the roles of teams. Monitoring is the first step in obtaining (and maintaining) an overview. However, accurate notification and alerting is also required for the various teams to be able to quickly respond to errors and interruptions in accordance with their respective (and often complex) roles and responsibilities. This is where a combination of Paessler PRTG monitoring software and alerting and notification functionality from SIGNL4 comes into play.

IT/OT convergence provides for new roles and duties

In modern manufacturing facilities, machines are networked with and connected to control and monitoring systems. In recent years, this merging of IT and production has led to a high level of integration between IT and OT. With ever more automation and IT systems used in production, IT is becoming increasingly responsible for supporting and monitoring manufacturing processes. IT is now at least partly responsible for ensuring smooth production processes, compliance with quality standards, and efficiency. For this to work, admins and other employees must be able to keep a constant eye on the performance and availability of all their systems. In other words, they need a monitoring solution that covers both IT and OT. Thanks to its native support for OT methods and protocols, PRTG is the perfect monitoring tool in the age of IT/OT convergence.

IT and OT monitoring with PRTG

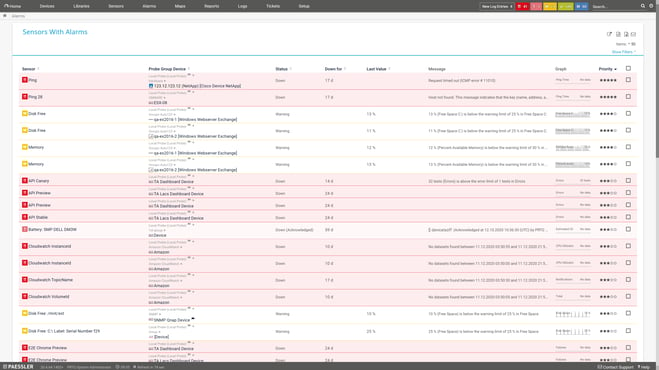

PRTG is an IT monitoring solution that monitors and analyzes the availability and performance of IT devices and systems. In addition to IT networks and infrastructure, PRTG can communicate with machines, controllers, and sensors in manufacturing environments (using methods such as OPC UA, Modbus, and MQTT), and integrate these devices into its central monitoring view. PRTG collects and displays the resulting data in easy-to-read dashboards. This allows for errors to be located quickly, which is much more important in manufacturing than in IT, as many problems must be fixed directly on the machines.

PRTG detects errors and downtime in near real-time, and alerts employees via SMS, email, push notifications, or other methods, so they can immediately troubleshoot the issue. Nevertheless, the focus of PRTG is on monitoring. And even though its notification system makes it possible to escalate issues, sometimes more is needed – such as taking service schedules into account, alerting by way of phone, or confirming and commenting on notifications.

PRTG detects errors and downtime in near real-time, and alerts employees via SMS, email, push notifications, or other methods, so they can immediately troubleshoot the issue. Nevertheless, the focus of PRTG is on monitoring. And even though its notification system makes it possible to escalate issues, sometimes more is needed – such as taking service schedules into account, alerting by way of phone, or confirming and commenting on notifications.

The more complex the monitoring scenario, the more precise the alerts must be. When it comes to comprehensively monitoring IT and OT environments, different teams are often responsible for different areas. While PRTG provides comprehensive alerts and notifications, it’s not always easy to fine-tune notification rules in PRTG for every individual situation. But when you integrate PRTG with SIGNL4 from Derdack, this becomes a cinch.

Precise alerting with SIGNL4

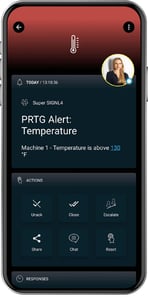

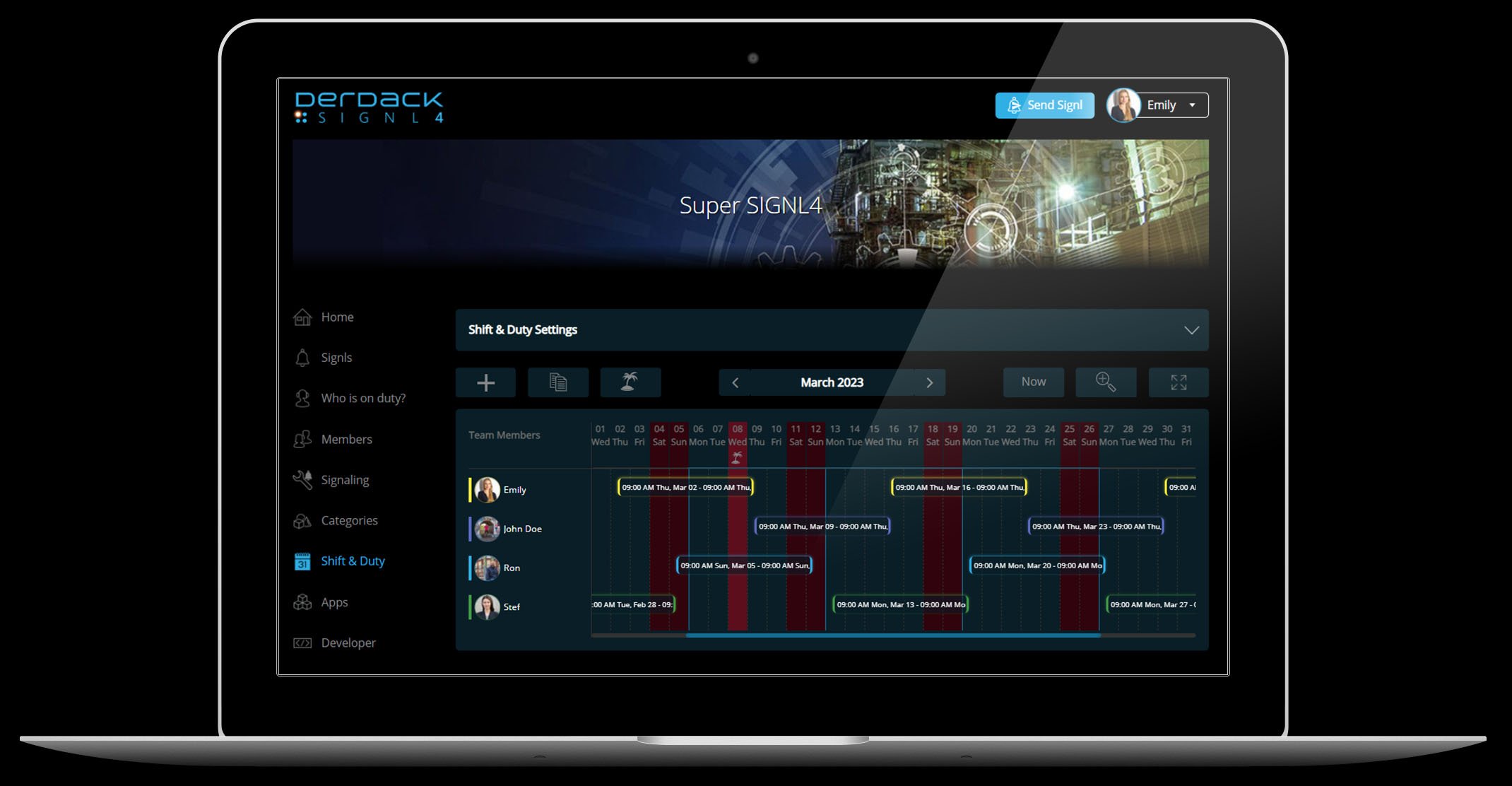

SIGNL4 brings to PRTG an advanced app-based alerting solution that can send alerts and notifications to responsible parties in real time. SIGNL4 alerts production managers or employees (as well as other relevant staff) quickly and precisely via a mobile app push notification or a phone call whenever problems occur in manufacturing processes or IT systems. It also takes into account on-call and service schedules, and helps escalate issues all the way up to managers.

SIGNL4 brings to PRTG an advanced app-based alerting solution that can send alerts and notifications to responsible parties in real time. SIGNL4 alerts production managers or employees (as well as other relevant staff) quickly and precisely via a mobile app push notification or a phone call whenever problems occur in manufacturing processes or IT systems. It also takes into account on-call and service schedules, and helps escalate issues all the way up to managers.

Services are conveniently scheduled via a web browser, while the mobile app provides employees with an overview of upcoming shifts. In addition, SIGNL4 allows for mobile chats in real-time between individual employees or teams, who can subsequently coordinate their responses to alerts and notifications while sharing updates and other information. Along with the acknowledgment of alerts, this allows for real-time, on-the-go handling of incidents. And thanks to the 2-way integration, all information is also immediately visible in PRTG.

PRTG and SIGNL4 work together to secure production and IT

By combining the IT and OT monitoring capabilities with the SIGNL4 mobile alerting and incident response tool, you can significantly reduce MTTR (mean time to repair) and help reduce (or even prevent) downtime. Production managers and service technicians will be able to confidently go about their everyday tasks, knowing that they will be notified of critical issues even if they are not directly in front of the dashboard or machine.

The precise alerting of an on-call service can prove to be extremely beneficial, especially when malfunctions or failures occur outside regular business hours or the respective employee can only be reached by phone.

Truma, an expert in heating and mover systems for RVs, uses PRTG and Derdack to secure its production and IT: Truma secures its production, business processes, and IT with Derdack and PRTG (paessler.com)

Published by

Published by

.jpg)