We love technology. It's what drives our developers. It's what drives our product. It's what drives our marketing. We try to avoid jumping on the bandwagon of every new IT buzzword that's out there—at least if it isn't directly related to a possible application for our customers.

Internet of Things basically means everything is connected, with all its advantages and disadvantages. For the network administrator of the future, this rising complexity will come with a whole new set of challenges. Forget about BYOD (Bring Your Own Device) and start thinking about BYOT (Bring Your Own Thing)—and "thing" could be, if you follow recent IT media articles, everything from a coffee machine to a car that's parked in the underground parking lot of a company. Especially wearables (electronic devices you wear on your body) seem to be one of the first trends within this almost infinite area of applications.

Who Monitors the Monitor?

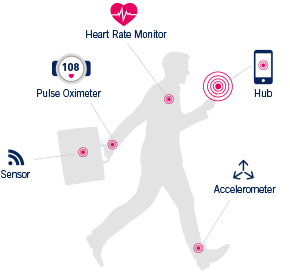

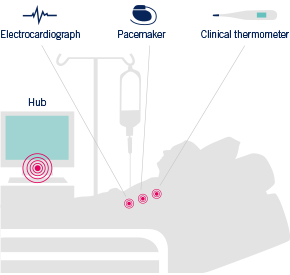

Wearables often are intended to be used for extended healthcare purposes, for example monitoring a patient's pulse or heart-rate. If there's a sudden drop in the heart-rate, an ambulance could automatically be informed, find the patient via GPS signal and hopefully save his life—but what happens if the software crashes, the device gets disconnected or is simply turned off? The recipient of the body monitoring data also has to be informed about the status of the wearable. You have to monitor the device in order to being able to guarantee a constant flow of reliable body monitoring data. For hospitals equipping their patients with these kinds of wearables, the integration into their IT environment is only a first step. They also have to think about updating their network monitoring strategy. Remember, everything will be connected.

One of the biggest challenges will be to integrate a very heterogeneous group of devices into an already existing network structure. This is even truer for companies in industries with a huge scope of possible "things" to integrate into their network.

The Intelligent Industrial Network: Industry 4.0

Also in the manufacturing industry wearables that, for example, measure the noise exposure of factory workers could be a realistic scenario—but that's just the beginning: imagine assembly lines that are never affected by unplanned downtimes, maintenance work that can be scheduled to an exact point in time, and spare parts that arrive even before a replacement is necessary. No more warning lights that only flash after an error has occurred or after a part has exceeded its life cycle.

This development is known under different terms like Smart Manufacturing or Industrial Internet—in Germany it is called Industry 4.0, which refers to the fourth industrial revolution and was initiated as a project in the high-tech strategy of the German government. The goal is to create intelligent networks along the entire value chain, which can control each other autonomously. Although we might yet stand at the beginning of this revolution, it's important to start planning for the future now. Especially the sensible integration with the existing IT infrastructure should not be taken lightly. What's happening to the data that gets picked up off the machines? It has to be added to the central IT system in order to enable further processing, useful display and a basis for maintenance workers to take action. Monitoring things, in this case complex industrial machines, isn't so different from monitoring network devices—what matters is getting relevant data that can be analyzed and put to a purpose.

The Evolution of Monitoring

As with the different stages of the industrial revolution, also IT is an area that never stops evolving—and network monitoring is a big part of this development. When the concept first was introduced, the technology mostly was used to monitor physical IT devices (Monitoring 1.0), like routers or switches. With the ongoing virtualization of networks, new concepts and functionalities had to be found (Monitoring 2.0) in order to gather and process new kinds of relevant data. The next logical step was to run applications in the cloud and even further extend the virtualization. To enable users of SaaS (Software as a Service) solutions and other cloud applications constant access to their productive environment, the connection to the cloud has to be closely monitored (Monitoring 3.0)—this includes the monitoring of services and resources from every perspective to guarantee the smooth operation of all systems and connections within the cloud.

Besides the necessity to continue monitoring all devices, virtual machines and cloud based applications, which have been monitored in the past, the Internet of Things also launches a new era in network monitoring (Monitoring 4.0) as with every new thing connected to the network, also the amount of data that can and should be monitored, is constantly growing. Due to the heterogeneous nature of "things" and applications, many of which we probably even can't think of today, it will be difficult to have an out-of-the-box solution that covers every possible scenario. Applying custom sensors is a feasible solution, already used by many of our customers. In the past we've seen users of PRTG Network Monitor being on the forefront of creativity, using custom sensors to monitor prawn farms, pellet stokers or even the blood fridge of a hospital—all not being network devices, but "things". We're learning about new applications almost every day and are excited about this development. Based on our customer's feedback, we're constantly improving PRTG and implementing new features, so that when the time has come, our customers will be able to monitor every "thing", they want.

If you can think of an exciting thing to monitor, or even have written a custom sensor yourself, let us know: mot@paessler.com

Published by

Published by