Generally speaking, gateways represent links between systems that are not necessarily compatible, and thus enable communication between them. In this context, the term "system" can refer to networks, individual computers, networked devices, or even various applications. So, for example, a fax machine that receives an incoming fax and forwards it as an e-mail could be considered a gateway.

In today's world, where almost all infrastructures are based on IP (Internet Protocol), gateways have fallen somewhat into the background. However, the rise of the Industrial Internet of Things (IIoT) has brought gateways back into the spotlight in industrial IT.

Industrial gateways and the tasks they perform

In industrial IT, retrofitting allows devices that communicate only via radio protocols trimmed for efficiency or proprietary data buses to now also be controlled via IP. Existing equipment is thus upgraded to a level that enables it to use the new technologies.

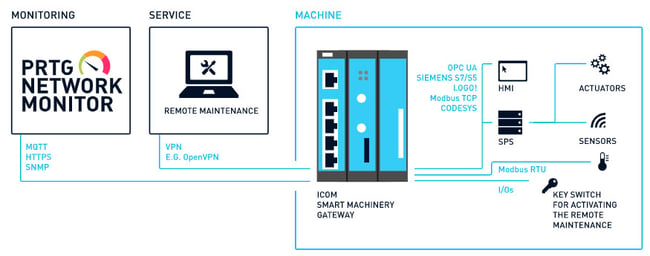

In the process, industrial gateways perform a protocol conversion and convert incoming data. As a result, systems or machines can not only be maintained remotely, but also controlled remotely, which allows technicians to be dispatched more efficiently.

|

💁 What is retrofit? Retrofit is made up of the Latin retro (backwards) and the English fit (to adapt). A retrofit is therefore an existing product that has been improved to meet current requirements. The modernization of plants is a favorable possibility compared to the purchase of new plants to increase energy efficiency, improve production quality, extend the service life of the plant and meet current legal requirements. |

3 reasons why you should monitor your gateways with PRTG

-

PRTG combines two worlds – IT & OT

Historically, monitoring solutions usually focused on IT-only infrastructures. PRTG combines the two worlds of IT and OT infrastructure and thus enables a central overview in one tool. By using gateways, which are offered by various well-known manufacturers, even older plants or machines can be integrated and monitored. With PRTG, we offer a solution that enables the integration of IoT scenarios beyond standard IT monitoring through a well-documented API and support for various protocols such as MQTT, Modbus, OPC-UA or JSON. -

Various alerting methods enable a faster reaction

PRTG provides a variety of notification options. This means that in an emergency, the right information can be sent to the right person in order to fix problems or failures as quickly as possible. A combination of role and authorization systems and flexible notification options ensures that alarms are noticed by responsible people in the shortest possible time. Customizable maps and dashboards additionally visualize errors and faults, which enables targeted problem solving and reduces troubleshooting time. -

Condition Monitoring keeps your environment up and running

Maintenance intervals, which are usually defined by the manufacturer, rarely accurately represent the condition of the machinery or equipment. Intensity and fluctuating usage influence the need for maintenance. If the defined schedule is followed, the maintenance measures could be too early or too late - where the latter can mean the failure of a machine or plant and have financial consequences.

Through individually defined threshold values of individual sensors, you are always informed about the condition of your infrastructure and maintenance measures can be carried out proactively and at the right time.

Digitalization and IT/OT convergence are bringing the worlds of IT and production together. This requires a monitoring solution that provides a dashboard for everything worth knowing from both worlds. Through a manufacturer-agnostic monitoring to check and map both IT and OT environments, PRTG helps you to reduce complexity and bring the worlds of IT and OT together.

Our OPC UA, Modbus, and MQTT sensors allow us to "speak OT", while providing all relevant IT protocols like SNMP, WMI, REST, and SSH within the same product. Centralized IT/OT alerting reliably notifies you with the right information to act quickly in case of a problem. Customize it to your needs and avoid alerting noise.

Connecting Node-RED based gateways with PRTG

If you are using or thinking about purchasing a Node Red-based gateway, such as those from INSYS icom or Advantech, the integration is greatly simplified, thanks to the Node-Red connector. Node-RED provides a browser-based flow editor that makes it easy to wire together flows using the wide range of nodes in the palette. Flows can be then deployed to the runtime in a single-click.

For both of these gateway vendors, we have created solution briefs about how to integrate your gateway data into PRTG:

👉 Download: Gateway solution brief: INSYS

👉 Download: Gateway solution brief: Advantech

Both solution briefs, additional information about IIoT Gateways, and how to integrate them in 4 steps can also be found on this page.

Are you already using gateways in your manufacturing environment? What are your experiences? We’re looking forward to your comments!

Published by

Published by