SCADA systems provide an overview of your Operational Technology environment. But in today’s connected OT world, they might not provide a comprehensive overview of all the important elements. Networked components, like routers, switches and more are often the domain of the IT department, and they often don’t communicate using OPC UA (a standardized communication protocol for modern industrial automation systems). The end result? Your traditional SCADA system does not provide a comprehensive overview of the status or data of your vital IT equipment.

The data I am referring to is monitoring data about the status of devices that support your OT connectivity. For example: are all the ports on your industrial routers working correctly? What is the CPU usage of your industrial PCs? What about acknowledging alarms generated by issues with these devices? These are generally not questions that can be answered by data that’s in your SCADA system.

For environments with OPC UA-based SCADA systems, tools like our Paessler PRTG OPC UA Server provide the bridge between these network devices and the OT overview. But maybe the benefit of including these networked devices in your SCADA system is not clear. Perhaps it’s not something you’ve considered before. To make things clearer, I will give you three examples of benefits from three different industries.

For environments with OPC UA-based SCADA systems, tools like our Paessler PRTG OPC UA Server provide the bridge between these network devices and the OT overview. But maybe the benefit of including these networked devices in your SCADA system is not clear. Perhaps it’s not something you’ve considered before. To make things clearer, I will give you three examples of benefits from three different industries.

Enrich existing time series data (for example in OSI PI Data Historian)

Data historian systems are commonly used in OT environments to collect and analyze data over time. Often, this kind of data collection is required to meet certain standards. For example: in the food and beverages industry, the Good Manufacturing Principles prescribes what data should be collected. Because of this, OT environments in the food and beverage sector probably already have a data historian in place. But this data is usually limited to OT data.

Let’s take an example of a company that produces sugar. They are using OS PI Historian to collect and view their time series data. But something is missing: An important metric to view over time is also the state and condition of IT equipment that supports their production environment. If this data is not in OSI PI Historian, it means that they are not analyzing the full picture.

This is exactly where a solution like Paessler PRTG OPC UA Server can help. Our sugar manufacturer is probably already monitoring the metrics of network devices using monitoring software – in our case, Paessler PRTG. With PRTG OPC UA Server, they have the option to get this monitoring data into OSI PI Historian.

The end result is an enrichment of the data already in OSI PI Historian, and provides a much more comprehensive picture for analysis of the production processes over time.

Holistic visualization of the OT environment

As already mentioned earlier, OT and IT data is often monitored separately, by separate teams. To demonstrate this, let’s consider how a typical wind farm operates: A SCADA system is used to monitor and remotely control the turbines, operational parameters, energy output, optimal performance and integration with the power grid. But in order to control the wind turbines, they need to communicate with them using more traditional IT components like routers and switches.

Let’s consider an example once again. A router or switch that allows connectivity within the wind farm network fails. The impact of this failure is that data flow from the turbines to the SCADA system may be disrupted. As a result, the turbines' real-time monitoring and control could be compromised. This means the operators could be unable to adjust to situations like changing wind conditions, resulting in inefficient energy generation or even turbine damage.

So these IT components are critical. But if they're not visible in the SCADA system, then the OT technicians’ insight into the status of communications with the wind turbines is limited. For this reason, it makes sense to provide data about these IT components in the same SCADA system where technicians supervise and control the wind turbines.

In an OPC UA-based environment, Paessler PRTG OPC UA Server can be used to bring data from these components into an OPC UA-based SCADA system for a much more holistic visualization of not only the wind turbines, but also their connectivity.

Enable OT and IT teams to work more efficiently together

Perhaps the most important benefit of having a single overview of both IT and OT elements in a SCADA system is that it enables IT and OT teams to work together in a coordinated way. After all, issues with networked components can potentially have a major impact on production.

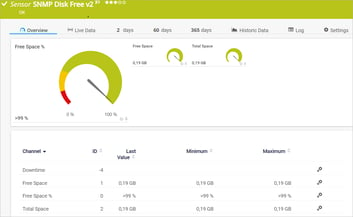

This was highlighted in August 2023, when Toyota had to shut down 14 of its Japanese factories, including 28 assembly lines. The reason? Systems that handle part orders were unavailable. Turns out that after a system update was performed, an “error occurred due to insufficient disk space”. Although the error was not in OT, it directly impacted manufacturing: Toyota’s business model of just-in-time means that parts are ordered at the points in assembly that they are needed. With the part ordering system offline, manufacturing came to a halt, resulting in a loss of revenue that some estimates place at $356 million US dollars.

This was highlighted in August 2023, when Toyota had to shut down 14 of its Japanese factories, including 28 assembly lines. The reason? Systems that handle part orders were unavailable. Turns out that after a system update was performed, an “error occurred due to insufficient disk space”. Although the error was not in OT, it directly impacted manufacturing: Toyota’s business model of just-in-time means that parts are ordered at the points in assembly that they are needed. With the part ordering system offline, manufacturing came to a halt, resulting in a loss of revenue that some estimates place at $356 million US dollars.

While the finer details of the outage are not known, it’s safe to assume that having the disk space of the relevant servers visible in a SCADA system – or at least the alarms when disk space was getting low – could have helped prevent the issue. Furthermore, an integrated solution makes it possible for IT teams and OT teams to cooperate through acknowledging alarms and better communication using one platform – usually the SCADA system.

In fact, this was one of our primary goals with Paessler PRTG OPC UA Server: to enable OT technicians to better handle the convergence of IT and OT.

Paessler PRTG OPC UA Server to bring OT and IT together

So these examples demonstrate that there is a very clear benefit to including your network and IT components in your SCADA system. In OPC UA based environments, you can use Paessler PRTG OPC UA Server to bring in IT data from PRTG into your SCADA systems. Depending on your needs, there are different levels of licenses and pricing available. If you’d like to discover more about PRTG OPC UA Server, get more information here or request a meeting with one of our industrial monitoring experts.

Published by

Published by